How to Size Cable Correctly for Commercial Installations

How to Size Cable Correctly for Commercial Installations

In commercial sites, cable sizing is never just a box-ticking exercise. In the UK, electrical fires are associated with an estimated 46 deaths and 2,469 injuries each year, so getting the “right-sized” cable is a genuine safety decision as well as a compliance one.

For electricians, facilities managers, and contractors, this guide explains what right-sized really means: safe operation, compliance, uptime, and lower lifetime cost. It will help you handle real-world conditions (grouping, temperature, run length and fault levels) so you can stop relying on rule-of-thumb guesses and start doing confident commercial cable sizing.

Cable Sizing Fundamentals (What Actually Determines Cable Size)

Start with The Load: Design Current and Duty Cycle

Everything begins with the load profile. A cable feeding an always-on extract fan is a different proposition to a shutter motor that runs for 20 seconds at a time, even if the nameplate currents look similar.

Typical commercial loads include:

- Lighting circuits and control gear

- Socket circuits and small power

- HVAC (fans, pumps, chillers)

- Motors and inrush-heavy equipment

- Submains feeding distribution boards

A practical habit is to write down what “normal operation” looks like (hours, simultaneity, cycling). That single note often explains why a circuit runs warm or trips during peak demand.

Ampacity vs Voltage Drop vs Fault Protection: The Big Three

Correct BS 7671 cable sizing is really three checks working together:

- Current-carrying capacity (ampacity): Your starting point is the cable current rating under the chosen installation method, then you derate for real conditions.

- Voltage drop: Long runs can quietly ruin performance, particularly where equipment is sensitive or inrush is high.

- Fault protection: The protective device must disconnect quickly enough, and the earth path must be good enough to make that happen.

It’s normal for one of these checks to become the deciding factor. On short, heavily loaded runs, ampacity dominates. On long distribution runs, voltage drop calculation often becomes the limiting factor.

Conductor Size, Insulation Type, and Installation Method

Cable size in mm² is simply the cross-sectional area of the conductor. Larger mm² generally means lower resistance and higher current capability, but it’s not the whole story.

Why the same mm² can have different usable ratings:

- Insulation type: PVC, XLPE and LSF/LSZH each has different temperature performance and use cases.

- Installation method: Clipped direct, in conduit, on tray, in trunking, buried, or surrounded by insulation all change heat dissipation.

- Environment: Temperature in risers, plant rooms, ceiling voids, and external routes can be very different from “standard” assumptions.

Step-by-Step Method to Size A Cable for Commercial Installations

Step 1: Calculate Design Current Ib (And Apply Diversity Where Appropriate)

Start with nameplate ratings and realistic maximum demand. Diversity can be sensible on mixed-use boards, but it becomes risky when loads are genuinely simultaneous or when a site is likely to expand.

Use diversity carefully:

- Suitable for offices and mixed tenancy where not everything runs together.

- Risky for process plant, kitchens, server rooms, and sites with uncertain future fit-out.

Step 2: Choose the Protective Device and Check Cable Rating Factors

Select the MCB, MCCB, or fuse to suit the circuit and environment, then check your effective cable current rating once correction factors are applied.

Common derating drivers in commercial installs:

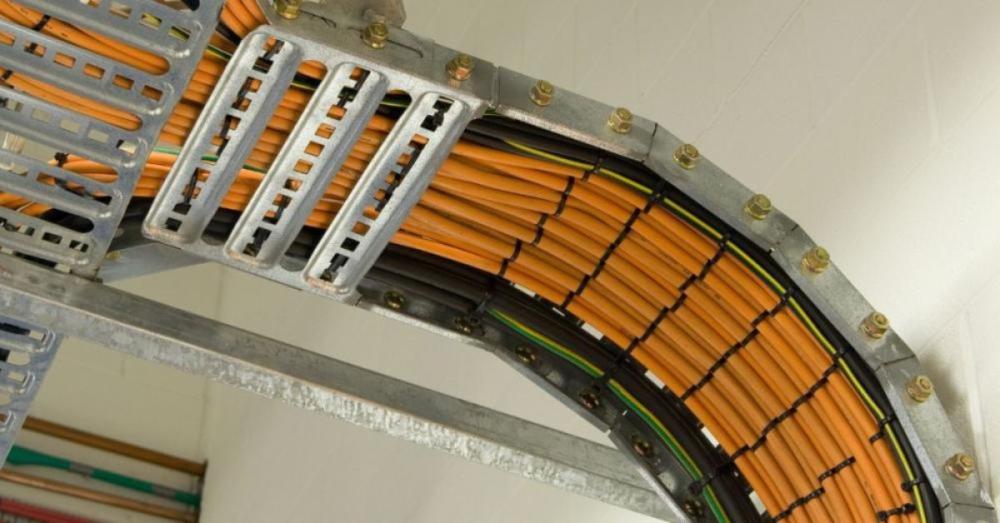

- Grouping of multiple circuits on tray or trunking

- High ambient temperatures, especially in risers and plant rooms

- Thermal insulation around the route during refurbishment works

- Harmonics from LED drivers, UPS systems, and IT loads

If the containment will be crowded, design with margin early. Upsizing later is rarely tidy or cheap.

Step 3: Verify Voltage Drop for The Run Length and Load Type

For UK design, BS 7671 commonly uses 3% voltage drop for lighting and 5% for other circuits supplied from a public LV system, which is why long runs demand attention. Warehouses, car parks, outbuildings and plant rooms routinely create the kind of run lengths where voltage drop, not ampacity, dictates the final conductor size.

Also, think beyond the steady state:

- Motors can dip voltage on start, which may lead to contactor chatter.

- Some lighting control gear and drivers behave poorly when voltage is low at the far end.

Step 4: Confirm Fault Current Withstand and Disconnection Performance

Check prospective fault current (PFC) at the board, confirm the protective device characteristics, and verify the CPC (earth conductor) and terminations support correct disconnection. A bigger live conductor chosen for voltage drop does not automatically mean the rest of the design is safe, so keep protection and earthing in the same calculation loop.

Step 5: Document and Label for Handover (Facilities Manager-Friendly)

A well-sized installation is easier to maintain when the facts are recorded. Capture:

- Cable type, conductor size, and core count

- Route and installation method

- Protective device details

- Test results plus design assumptions (including diversity)

This reduces downtime because the next person is not guessing what’s in the trunking or why it was chosen.

Choosing the Right Cable Type for The Environment

Indoor General Circuits: When Twin & Earth (T&E) Makes Sense

T&E is a common choice for straightforward indoor, single-phase circuits such as lighting, sockets, and switching. In commercial containment, pay close attention to grouping and route temperature, because those are the two factors most likely to undermine your intended cable current rating.

Outdoors, Underground, And High-Abuse Areas: When SWA Is the Safer Choice

For exposed routes, external walls, service yards and underground runs, armour often makes sense. Good SWA cable selection is less about copying a previous job and more about matching the route conditions and installation risk.

Core selection tips:

- 2-core, where a single-phase load and design allow

- 3-core for many common power and distribution scenarios

- 4-core or core plus earth arrangements, where the design calls for it

Plant Rooms, Panels, And Control Wiring: Tri-Rated and Flex Options

Tri-rated cable is typically a strong fit for panel wiring and controls where neat terminations and identification matter. Flex cable is usually the better choice where movement, vibration, or regular access is expected, because it handles mechanical stress at terminations more gracefully.

Fire Performance and Compliance: LSF, Fire-Resistant, And Critical Circuits

LSF/LSZH is often specified where smoke and toxicity reduction is required, especially in occupied buildings and escape routes. Fire-resistant cabling may be required for life safety systems where the spec demands it, so treat it as a compliance-led decision rather than a purely cost-led one.

Source - eFIXX

Conclusion: Buy with Confidence and Reduce Installation Risk with Meteor Electrical

If you remember one workflow, make it this: load, protection, derating, voltage drop, fault performance. When those checks line up, you get circuits that run cooler, trip less, and stand up to inspection.

Meteor Electrical stocks a wide range of cable types and sizes (including T&E and SWA) across multiple brands such as PXCABLES and Zahler. Do confirm colour, size and length before checkout, since the cable is cut to specification and is typically non-returnable.

Head over to Meteor Electrical and spec your cable with confidence today!

FAQs

1. How do I calculate cable size for a three-phase commercial load?

Calculate the design current per phase, then verify ampacity, voltage drop and fault protection for the actual installation method.

2. What is more important: amp rating or voltage drop for long cable runs?

On long runs, voltage drop can be the limiting factor even when ampacity looks fine, and BS 7671 commonly uses 3% for lighting and 5% for other circuits as design targets.

3. How does grouping on cable tray affect current-carrying capacity?

Grouping traps heat, so derating applies and the effective cable current rating drops, which often forces an upsized conductor.

4. When should I use SWA cable instead of Twin & Earth or NYMJ?

Use SWA where mechanical protection is needed, such as outdoors, buried routes, or high-risk areas, and use T&E or NYMJ where the environment and containment suit their intended applications.

5. Why are cable orders often non-returnable, and how do I avoid ordering mistakes?

Because cable is commonly cut to the customer’s length, suppliers typically treat it as non-returnable; avoid mistakes by confirming type, cores, size, colour and length before ordering.