Conduit Buying Guide: PVC vs Steel vs Flexible - When Each Makes Sense on Site

Conduit Buying Guide: PVC vs Steel vs Flexible - When Each Makes Sense on Site

Electricians and facilities managers often encounter tough choices on-site in terms of the conduit selection for cable management. The improper selection may result in serious problems in the future, including broken pipes or inspections. However, the main question arises, "Why choose a relevant type of conduit over another? So, this guide presents the pros and cons of PVC, steel, and flexible conduits based on examples in trade so that the electricians and the facilities managers can make sound decisions in adopting durable Cable Management and know which one to match what.

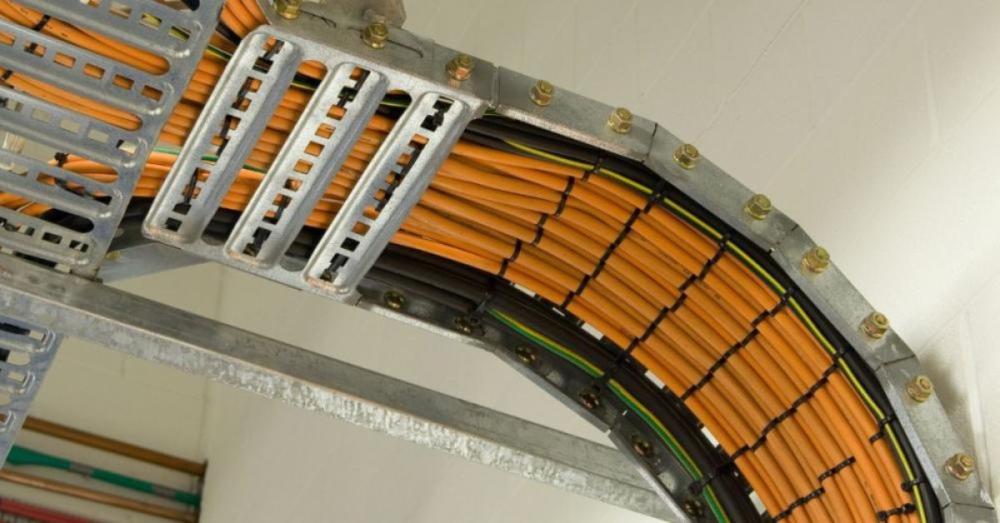

Why Conduit Matters in Cable Management

Conduit forms the backbone of effective Cable Management, shielding wires from physical damage, moisture, and interference while meeting BS 7671 standards. In commercial builds or industrial settings, it prevents costly call-backs by containing faults and easing future upgrades. Poor choice leads to corrosion, cracks, or inflexible routing issues that turn a quick job into a headache.

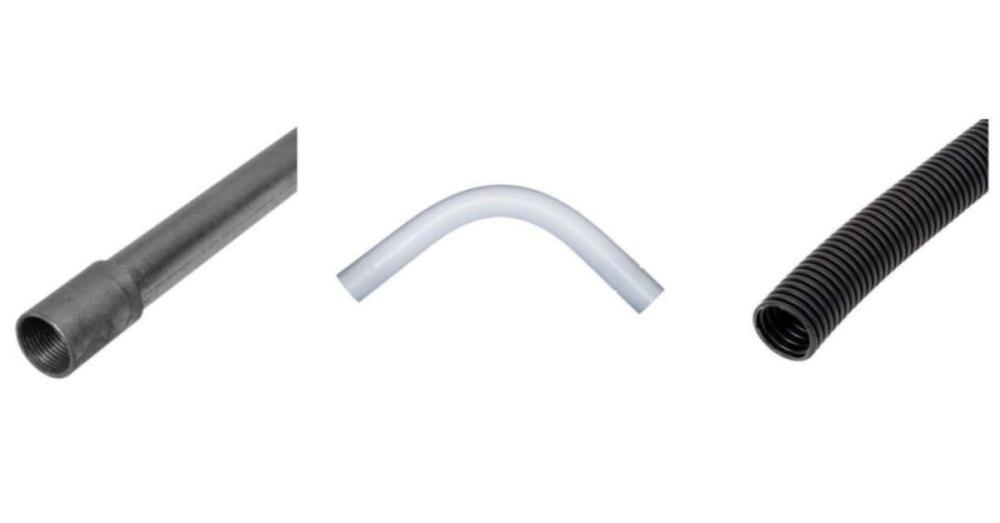

PVC Conduit: Lightweight and Cost-Effective

PVC conduit, often called plastic conduit, suits indoor and less demanding environments where weight and ease matter most. Made from durable polyvinyl chloride, it resists corrosion and is simple to cut with standard tools-no threading required. Ideal for Office Cable Management in suspended ceilings or walls, it installs quickly without heavy lifting and supports clean Cable Management Accessories layouts.

Use PVC when sites need non-conductive protection without high impact risks, like domestic refits or light commercial runs. It bends easily with heat guns for gentle curves and comes in sizes from 16mm to 32mm oval or round profiles. Avoid exposed outdoor spots or heavy traffic areas, as they can become brittle under UV or extreme knocks commonly seen in Home Cable Management projects.

Common pitfalls: Over-tightening clips cracks them; always use saddle clips for secure fixing.

Key PVC Products

20mm Galvanised Conduit 3m Length: No, wait, this is steel. For PVC: Round cable clips (14-20mm, white, 100/box) secure flex or conduit neatly with hardened steel nails, perfect for tidy surface runs in Home Cable Management.

25mm PVC intersection box joins conduits at right angles smoothly, ideal for branching wires without sharp bends that stress cables, and keeps installations neat and compliant while supporting organised Cable Management Accessories use.

Steel Conduit: Built for Tough Conditions

Steel conduit shines in harsh, high-risk zones, offering unmatched mechanical strength via its thick, galvanised walls compliant with BS4568. Galvanising prevents rust, making it suitable for damp basements, factories, or outdoor embeds in concrete where heavy-duty Cable Management is essential. Its conductivity allows it to double as an earth path in short runs, though dedicated wires are best.

Opt for steel on sites with vibration, impacts, or chemical exposure, like warehouses or submersible systems, where it protects against fire, EMI, and rodents. Sizes like 20mm, 25mm, and 32mm handle heavy loads, with threaded ends for robust joints. Drawback: heavier, so factor in extra manpower for long straights.

Pro tip: Ream cut ends to avoid wire insulation damage; use set-screw couplings for vibration-prone spots.

Key Steel Products

Three lines intro: Steel options deliver heavy-duty Cable Management Accessories for industrial reliability. Here's what stands out.

20mm galvanised conduit (3m length): Hot-dipped steel with class 4 protection and threaded ends-great for outdoor lights or water features, shrugging off rain and frost effortlessly while supporting long-term Cable Management.

20mm galvanised flange coupling: Joins pipes securely in harsh warehouses; galvanised steel flange ensures a solid, rust-free link for long-term durability in demanding Office Cable Management or industrial setups.

Flexible Conduit: Navigate the Tricky Spots

Flexible conduit bends without tools, perfect for tight turns around light fittings, motors, or vibrating gear. Spiral designs in PVC-coated steel or plastic handle movement, with IP ratings like IP54 guarding against dust and splashes. Use it for dynamic installs where rigid options snag or crack, especially in adaptable Cable Management systems.

Choose flexible for Home Cable Management near appliances or Office Cable Management in awkward ceilings-it snakes through obstacles while damping vibrations. Not for straight, exposed runs; pair with glands for liquid-tight seals. The temperature range, often -15°C to +70°C, suits most UK sites.

Job advice: Limit fill to 40% capacity to pull cables easily; avoid over-bending beyond the minimum radius.

Source - eFIXX

Key Flexible Products

Flexible variants excel in Cable Management for bends and motion. Top picks include:

32mm PVC flexible conduit gland (black): Straight polypropylene entry seals flex into boxes, suits public buildings or industry with light protection needs and reliable Cable Management Accessories integration.

25mm x 50m PVC-coated steel flexible conduit: Galvanised core with black PVC sheath, IP54-rated for motors or AC units-handles static or dynamic jobs reliably in both Office Cable Management and industrial applications.

Quick Comparison Table

| Feature | PVC Conduit | Steel Conduit | Flexible Conduit |

|---|---|---|---|

| Best For | Indoor, light duty | Industrial, exposed | Tight bends, vibration |

| Strength | Good corrosion resistance | Excellent impact / fire | High flexibility |

| Install Ease | Easiest, lightweight | Heavier, threaded | No tools for bends |

| Cost | Lowest | Higher | Mid-range |

| Sites | Office / Home | Factories / Outdoor | Motors / Lights |

Best Practices and Mistakes to Dodge

Start with a site survey: map runs, check for damp or traffic. Always use manufacturer-approved Cable Management Accessories like clips, bends, and boxes-mixing leads to failures. Number 1: Calculate fill capacity strictly. Then number 2: Ground metal types properly and lastly inspect for damage post-install.

Avoid skimping on galvanising in wet areas or ignoring bend radii in flex, common errors sparking rewires. For Office Cable Management, blend PVC with trunking; for industrial, steel with locknuts.

Wrapping up:

Lastly, work with PVC when you need something fast at home, steel where you need heavy work, and flexible where you need complex work and match the materials and the task to work well with cables in both Home Cable Management and large-scale Cable Management projects. When your project is urgent, you can order quality stock from reliable wholesalers, like Meteor Electrical, and receive it the next day. Check out our website for more information and get everything you need!

FAQ Section

Q1. What’s the main difference between PVC and steel conduit?

PVC is lightweight and non-conductive for indoors; steel offers superior strength for harsh outdoor or industrial Cable Management use.

Q2. When should I use flexible conduit on-site?

For tight bends, vibrations, or moving equipment like motors, where rigid types won't fit within modern Cable Management layouts.

Q3. Is galvanised steel conduit rust-proof?

Yes, hot-dipped galvanising resists corrosion in damp conditions, per BS4568 standards.

Q4. Can PVC conduit go outdoors?

Best indoors; UV degrades it-use steel or rated flex for exposed weather, especially in long-term Home Cable Management installs.