All You Need to Know About Three Phase and Neutral TP&N Distribution Boards

All You Need to Know About Three Phase and Neutral TP&N Distribution Boards

A well-designed distribution system is the quiet hero of any building—safe, tidy, and always on. In this guide, we’ll demystify the components, the choices, and the wiring basics of TP&N boards so you can specify with confidence. We’ll also point you to trusted resources and standards, and show how Meteor Electrical can help you source the right gear for the job.

What is a Distribution Board?

Distribution boards, also known as consumer units, are essential components of an electrical supply system. They split the incoming electrical power feed into multiple secondary circuits, allowing for precise power supply control to different areas. These boards also isolate circuits during abnormal conditions, ensuring safe maintenance and operation. For a helpful overview of safe electrical practice for households, see the guidance from Electrical Safety First. Professionals should also be familiar with the IET’s Wiring Regulations (BS 7671), which underpin design and inspection.

Types of Distribution Boards

Different projects require different types and sizes of distribution boards to meet specific needs. Here's a detailed look at the main types:

Consumer Units

Consumer units are essential for residential and smaller commercial applications. Featuring main switches and RCBOs (Residual Current Circuit Breaker with Overcurrent Protection), these units offer reliable protection and isolation for each circuit. They are designed to safeguard against electrical faults such as overcurrent and short circuits, making them a popular choice for ensuring electrical safety. Want to learn more about consumer units? Watch this helpful guide to get you started.

Dual RCD Consumer Units

These units provide enhanced safety by including two RCD breakers (Residual Current Devices). This configuration effectively protects against electrical fires, overheating, and accidental contact with live wires. Dual RCD consumer units are particularly suitable for environments where additional safety measures are crucial, such as homes and office buildings. If you’re targeting UK searchers, one strong long-tail term here is dual RCD consumer unit UK—a good fit for buyers who already know what they need.

Source- John Ward (jwflame)

High-Integrity Consumer Units

Ideal for larger buildings with complex electrical systems, high-integrity consumer units combine dual RCD protection with additional RCBOs. This setup allows for flexible configuration and enhanced protection for multiple sub-circuits. These units are perfect for commercial properties and larger residential buildings that require robust and customisable electrical distribution solutions. Their appeal is simple: greater isolation, less nuisance tripping, and clearer circuit discrimination.

Three-phase Distribution Boards

Suitable for both commercial and home applications with higher loads, these boards offer up to 24-way circuit protection. Three-phase distribution boards are designed to handle significant power demand, making them ideal for industrial environments like warehouses and factories. They can be installed internally and externally, providing versatility for various project requirements.

Additionally, these boards often include components like TP&N isolators and busbars, ensuring efficient and safe power distribution. If your project brief mentions industrial electrical distribution boards, this is usually the category you’ll be shortlisting first.

Selecting the right type of distribution board is crucial for ensuring the safety and efficiency of your electrical system. Whether you need a consumer unit for a small installation or a high-capacity three-phase distribution board for a larger project, understanding the specific features and benefits of each type can help you make an informed decision.

Three Phase and Neutral (TP&N) Distribution Boards Explained

TP&N Distribution Boards function similarly to single-phase boards, splitting the power feed into subsidiary circuits while providing the necessary protection. They are designed for commercial environments like warehouses, factories, and other buildings requiring three-phase power. At Meteor Electrical, our range of TP&N distribution board options and accessories offer flexibility, allowing electricians to design efficient distribution systems within compact enclosures. The neutral bar supports single-phase loads on a three-phase supply, keeping layouts neat and discrimination clear—especially important when multiple circuits serve business-critical equipment.

Components of Three-Phase Distribution Boards

- Main Current Breaker/Main Switch: Limits the amount of electricity within the building, ensuring controlled power distribution and protecting against electrical hazards.

- Miniature Circuit Breaker (MCB): MCBs protect circuits from overcurrent, overload, or short circuits by disconnecting them during abnormal conditions.

- Residual Current Circuit Breaker with Overload Protection (RCBO): Combines RCD and MCB functions, providing comprehensive protection against earth fault currents, overloads, and short circuits—helpful where you want individual circuit protection.

- Isolators: Manually controlled devices that isolate parts of the circuit for safe maintenance, testing, or change-outs.

- Busbars: Metallic strips that transfer power from the incomer to the circuits, simplifying distribution and reducing wiring time and cost. Fully enclosed busbars offer an extra layer of safety and tidiness.

Choosing the Correct Three-Phase Distribution Board

Selecting the right TP&N (Three-phase and Neutral) distribution board is crucial for ensuring the safety, efficiency, and reliability of your electrical system. The correct choice depends on your specific project requirements, including the type of building, the electrical load, and the installation environment.

At Meteor Electrical, our Garo three-phase distribution boards are a popular choice for several compelling reasons:

Modern Design: Our distribution boards feature a sleek and contemporary design that seamlessly integrates into commercial or light-industrial settings. The modern finish with epoxy powder paint ensures durability and a professional look.

Compliance with Standards: All our three-phase distribution boards comply with BS EN 61439-3—the standard for distribution boards intended for use by ordinary persons (DBO). You can read more about this standard via the British Standards Institution (BSI). Including the phrase BS EN 61439-3 compliance helps align with specification-led searches.

High Loading Capacity: With a maximum loading current of up to 125A, our boards are designed to handle significant electrical loads, making them ideal for industrial applications such as factories, warehouses, and large commercial buildings.

Easy Installation: Features like keyhole fixings, removable gland plates, and fully enclosed busbar systems speed up first-fix and make modifications simpler. Clear labelling and generous wiring space support error-free commissioning.

Enhanced Features:

- Fully Enclosed Busbar System: Helps prevent accidental contact with live parts.

- Removable Gland Plates: Simplify cable entry and ensure a secure, tidy installation.

- Quick Installation: Earth and neutral terminals are laid out for efficient dressing and testing.

Versatility: Suitable for both internal and external installations, our distribution boards offer flexibility for varied project requirements—from plant rooms to service corridors and secure external enclosures.

When choosing a three-phase distribution board, consider your project’s load profile, environmental conditions (IP ratings, corrosion resistance), and discrimination/backup protection strategy. By selecting a high-quality, compliant distribution board like those offered by Meteor Electrical, you can help ensure long-term safety and performance.

Wiring of a 3-Phase Distribution Board

Wiring a three-phase distribution board can be a complex yet crucial task in ensuring the safe and efficient distribution of electrical power. The process involves integrating various components to manage and distribute electricity to numerous connected appliances. For workplace safety expectations, see the HSE’s guidance on Electrical safety at work.

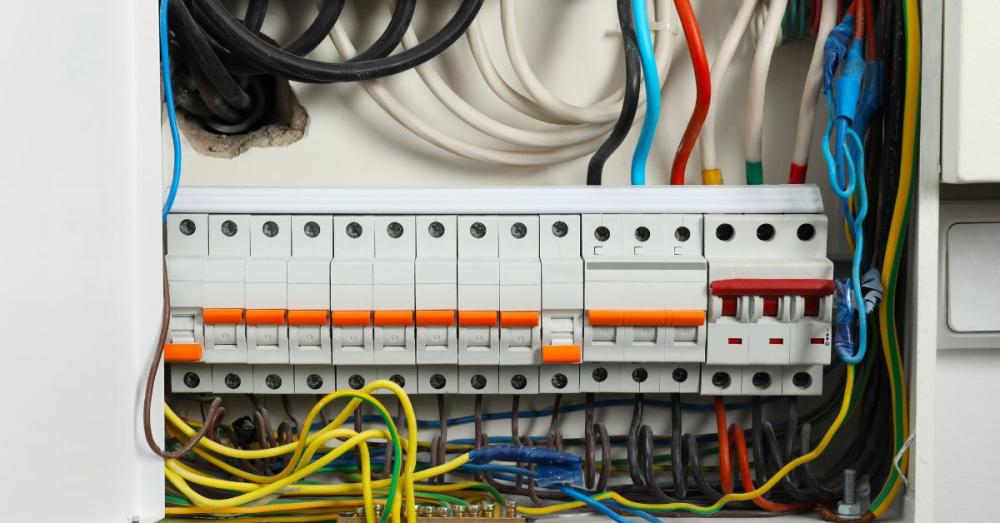

Key Components:

Double Pole MCB (Miniature Circuit Breaker): Provides protection by interrupting the power supply in case of overload or short circuit conditions. Double-pole MCBs control and protect two poles simultaneously, ensuring comprehensive safety.

RCD (Residual Current Device): Essential for protection against electric shock by detecting earth faults and disconnecting the circuit when a dangerous fault is detected.

Single Pole MCB: Protects individual circuits from overcurrent and short circuits. These are crucial for isolating faults so only the affected circuit is disconnected, minimising disruption.

Wiring Process:

Wiring a three-phase distribution board requires careful planning and precision. Here’s a general overview of the steps involved:

- Planning and Safety: De-energise the supply and confirm isolation before work begins. Assess load diversity, future expansion, ambient conditions, and the need for selectivity between protection devices.

- Mounting the Board: Securely mount the distribution board in the desired location with adequate working clearances. Ensure it is easily accessible for maintenance and inspection.

- Connecting the Main Power Supply: Terminate the incoming three-phase supply to the main switch or incomer: L1, L2, L3, and N. Confirm torque settings and use ferrules where required.

- Installing MCBs and RCDs/RCBOs: Fit the protective devices in designated ways. Keep high-priority circuits (e.g., servers, refrigeration) on RCBOs where appropriate for selective isolation.

- Wiring to Sub-Circuits: Dress conductors neatly, adhere to bend radii, and verify cable sizes to BS 7671. Use clearly labelled neutral and CPC terminations, with correct identification for phases.

- Testing and Verification: Complete continuity, insulation resistance, polarity, RCD/RCBO tests, and Zs checks. Record results on appropriate certification.

If you’re creating written documentation, target the long-tail phrase three-phase distribution board wiring—it maps closely to how installers search for methodical, step-by-step guidance.

SOurce - eFIXX

Understanding the Need for Three-Phase Power:

Three-phase power is essential for high-demand environments where single-phase supply is insufficient. It provides a more stable and efficient power supply for heavy machinery and large electrical loads, reduces voltage drop over distance, and allows smoother motor starting. The video below illustrates the layout of a three-phase distribution board, wiring diagrams, and scenarios where three-phase power is necessary.

In the video, you’ll learn about:

- Layout and Wiring Diagram: A visual guide to the layout of a three-phase distribution board and step-by-step wiring instructions.

- When to Use Three-Phase Power: Insights into situations where three-phase power is required, highlighting its advantages over single-phase power supply.

Conclusion

By following these guidelines and understanding the components and processes involved, you can ensure a safe and efficient wiring setup for your three-phase distribution board. Proper wiring is critical for the reliable operation of your electrical system, preventing potential hazards and ensuring consistent power distribution.

Ready to enhance your electrical system with a high-quality Three Phase Distribution Board? At Meteor Electrical, we stock a wide variety of high-quality distribution supplies such as three-phase RCBOs, RCDs, consumer units, metal and plastic enclosures, and more. Our products are sourced from reputable, highly rated manufacturers worldwide. Browse our selection here—and if you’re looking to rank locally, consider content clusters around industrial electrical distribution boards and location-specific service pages. our wide range of Garo three-phase distribution boards, RCBOs, MCBs, and accessories. For more information or to get personalised assistance, email us at [email protected] or chat with our friendly advisors on our website. Let's power your projects with safety and efficiency!

Frequently Asked Questions

Q: What is the difference between Type A and Type B Distribution Boards?

Type A distribution boards have a busbar layout designed to accept single—and/or double-pole OCPDs (Overcurrent Protection Devices), typically with a horizontal busbar. Type B distribution boards are configured to accept multi-pole and/or single-pole OCPDs. In practice, check the board schedule and way count to ensure compatibility with your chosen protective devices.

Q: Does a 3-phase system need a Neutral?

Yes, a neutral wire allows a three-phase distribution board to operate at a greater voltage while still supporting single-phase appliances that require lower voltage. In high-voltage distribution, a neutral line is not typically needed, as loads can be linked between phases. In buildings, a neutral is common because mixed loads (lighting, small power) need single-phase supplies.

Q: What is Phase 3 Electricity?

So what is phase 3 electricity? Phase 3 electricity, or three-phase power, uses three alternating currents to deliver electricity efficiently. It involves three conductors labelled L1, L2, and L3, which provide a continuous and balanced power flow—ideal for motors, HVAC, lifts, and process equipment.

Q: How does Phase 3 electricity differ from single-phase electricity?

Phase 3 electricity uses three conductors to carry electric current, offering more power and efficiency for handling heavy loads compared to single-phase systems, which use only one conductor. This typically results in smoother motor operation, better load sharing, and improved system efficiency.

Q: Where is Phase 3 electricity commonly used?

It is commonly used in industrial settings, manufacturing plants, commercial facilities, and large-scale operations where high energy demands are present. It powers equipment like motors, pumps, compressors, and industrial machinery. You’ll also see it in mixed-use buildings and larger retail spaces.

Q: What are the benefits of Phase 3 electricity?

The benefits include higher power capacity, balanced load distribution, smoother equipment operation, reduced power fluctuations, and improved efficiency—making it ideal for applications requiring reliable and efficient power transmission.

Q: How is Phase 3 electricity installed and maintained?

Proper installation includes ensuring balanced loads across all phases, adequate insulation, and using protection devices to prevent electrical faults and hazards. Regular inspections and maintenance ensure the reliability and safety of the electrical system. Always test and certify to BS 7671, and keep O&M documentation up to date.