Common Temporary Worksite Electrical Issues-and How to Solve Them

Common Temporary Worksite Electrical Issues-and How to Solve Them

Workplaces are rife with activity, especially when it comes to construction sites; they, however, lose their electricity in seconds due to electrical accidents. The sites are very active, and with activities come dangers, and all these dangers can pose a great risk to temporary electrical installations. The U.S. Occupational Safety and Health Administration (OSHA) announced more than 1,000 workplace injuries related to electricity in 2023, with quite a few caused by temporary arrangements. A bad circuit, poorly selected equipment, and faulty wiring can turn a productive day into a disaster. Just relax; there are some practical solutions to keep your worksite secure and in good running condition. As Thomas Edison once said, "There's a way to do it better-find it."

So, without further ado, let's dive straight into electrical problems at temporary work sites and know how to solve them using smart, workable solutions so that your people at the work site remain safe and productive.

Why Temporary Worksite Electrical Safety Shouldn't Be Temporary?

You may be tempted to believe that a temporary worksite does not require electrical safety of the highest calibre. Well, it is only a matter of a few months, isn't it? Wrong. There are chances that injuries or delays or even more may occur as a result of cutting corners here. Any project, long or short term, lives on safety.

- Compliance: Keeps you aligned with OSHA regulations.

- Protection: Safeguard your crew from harm.

- Reliability: Prevents unexpected power failures.

- Efficiency: Boosts workflow without interruptions.

- Confidence: Let everyone focus on the job.

Credit: Safelyio

What Makes Temporary Worksite Electrical Setups So Tricky?

Temporary worksites are a beast of its own. They are not as calm as a fixed location office or a factory, with tools scattered all over, cords crossing the dirt, and weather adding twists in the form of unpredictable conditions. It is difficult to establish a secure system of electrical activities in such a setting, yet proper equipment is able to make everything easy. These five products have tried and tested solutions to work site safety that are simple to operate.

ESP MAG2P 2-Zone Fire Panel: This compact fire panel is a lifesaver for small sites. It's quick to set up and detects fire risks early, keeping your crew safe.

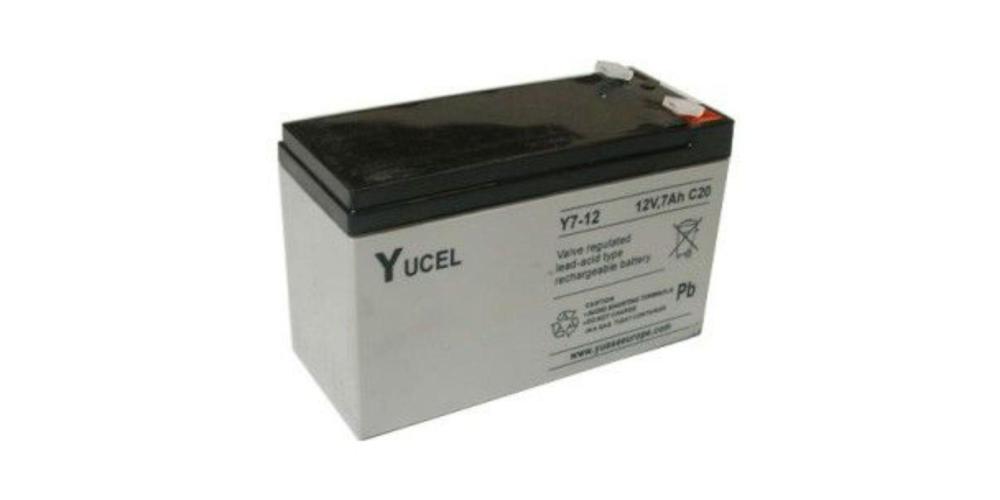

12 Volt 7.0 Ah Battery for MAG Panels: Power outages won't leave you vulnerable with this battery. It's a plug-and-play backup that ensures your fire panel stays online.

Firehawk FHN600 Test/Silence Remote Control: Testing alarms doesn't get easier than this handheld remote. It's portable, intuitive, and saves time when you're juggling a busy site.

Apollo Series 65 Optical Smoke Detector: This detector spots smoke fast, even in dusty conditions. Its simple design makes it a breeze to install and maintain.

CFP AlarmSense 2-Zone Two-Wire Fire Alarm Panel: Perfect for temporary setups, this panel cuts down on wiring complexity. It's cost-effective without skimping on safety.

These tools are built for the rough-and-tumble world of construction. They're not just reliable; they're designed to make your life easier so you can focus on getting the job done.

Credit: Safetyanimation

Common Overloading Problems Without Realizing It!

Overloading of circuits is equivalent to inviting chaos at your workplace. You have heavy equipment, power equipment and lightning all drawing off the same system. One can go a long way without realizing it until there is a breaker trip or something even worse. To simplify the most common problems of overloading and the ways of their resolution, let's consider them.

- Unintended usage of tools: high-powered tools should not all be plugged in simultaneously, as this overloads the circuits.

- Undersized wiring: Thin cables are inadequate and cannot meet the requirements of modern equipment; hence, they overheat.

- Uneven load distribution: Overloading of a circuit and keeping others idle result in frequent trips.

- Excessive use of extension cords: There are bottlenecks when daisy-chaining is used, and there is a potential for fire.

- Ignoring power ratings: Running outlets or circuits more than they are rated could be a welcome error.

The Solutions to fix them:

- Calculate loads accurately before setup.

- Use weatherproof distribution boards for durability.

- Install industrial plug sockets for heavy-duty needs.

- Add circuit breakers to prevent overloads.

- Incorporate RCDs for extra protection.

- Monitor power usage with regular checks.

Taking these steps ensures your electrical system can handle the demands of a busy worksite. It's about planning ahead and using the right tools to avoid surprises.

Fire Hazards: Is Poor Equipment Choice Putting Your Site at Risk?

A single spark is enough to turn any worksite into a disaster zone. Faulty wiring, low-cost extension cords or outdated fire detection gear can worsen small problems into full-blown fires. Spending on quality equipment not only makes sense, but it is also the key to keeping your site and crew safe, items such as quality smoke detectors and fire panels.

Final Thoughts:

It does not take a small operation to run a temporary worksite. You have timeframes, finances, and a million moving parts. But skimping on electrical safety? It is too much of a risk to take. Just a tiny bit more time invested in selecting the right equipment properly, say, a fire panel, smoke detectors, as well as reliable distribution boards, can protect you against the expensive losses caused by downtimes or equipment and may even prevent injuries.

Safety is not a rule. Rather, it is the basis of a successful project. We have some tried and tested site-ready electrical products suited to all of your needs and worksites at Meteor Electrical. Check out our gear and make safety your first step.