Underground Cable Conduit: Ultimate Guide to Secure and Compliant Wiring

Underground Cable Conduit: Ultimate Guide to Secure and Compliant Wiring

Installing electrical wiring underground requires planning, robust materials, and adherence to regulations, especially when dealing with underground cable conduit systems. A poor installation can result in water ingress, rodent damage, or safety failures. The Health & Safety Executive (HSE) and BS 7671 electrical standards mandate proper protection for external wiring to avoid hazards and ensure longevity.

In this guide, we’ll walk through key conduit types, installation depths, protection methods, and a new section on trench planning and marking. By following these best practices, you can install outdoor electrics safely and reliably, whether you’re a homeowner or an electrician.

Which Conduits Are Placed Underground?

Not all conduit systems are built for outdoor installation. Some excel indoors but fail to protect effectively below ground. Here are the most commonly used external conduit methods:

Electrical Metallic Tubing (EMT)

- Flexible, galvanised steel, and bendable with a conduit bender.

- Suitable when used with watertight fittings.

- Ideal for light external installations.

- Requires regular inspection as clamp set‑screws may loosen; torque tools are strongly recommended.

Rigid Metal Conduit (RMC)

- Toughest underground option, made from aluminium or stainless steel.

- Highly protective, puncture and crush-resistant.

- Best for high‑risk zones but requires specialised tools and costs more upfront.

PVC Conduits

- Lightweight, corrosion-resistant, and very easy to install.

- Ideal for trenching in soil or concrete.

- Suitable for burial at protected depths (e.g. 300–450mm).

- Outdoor cable conduit systems often rely on PVC when flexibility and cost are priorities.

What Is the Best Underground Cable Conduit?

With so many options, choosing the right one can feel overwhelming. The best choice depends on several factors:

- For maximum durability and compliance, Rigid Metal Conduit buried at 300mm+ offers unmatched protection.

- For easier installation and moderate protection, PVC conduit with UV-stabilisation works extremely well in residential and light-commercial settings.

- For shallow runs or where mechanical stress is low, EMT with watertight fittings can be a practical choice.

At Meteor Electrical, you can explore an extensive range of underground cable conduit systems, from galvanised steel to flexible PVC trunking, available in 20mm, 25mm and larger diameters.

How to Choose the Best Underground Cable Conduit

When selecting the right conduit, consider the following:

Location and Environment

- Is the conduit exposed to impact, chemical exposure or constant moisture?

- Choose corrosion-resistant materials like stainless RMC or UV-safe PVC where appropriate.

Budget vs. Performance

- While metal conduits offer superb durability, PVC provides excellent protection at a lower cost.

- Evaluate lifecycle costs: a robust conduit may reduce future repairs or rewiring.

Ease of Installation

- EMT and PVC are easier and less labour-intensive than RMC.

- PVC is lighter, quicker to trench, and can handle gentle curves easily.

Regulatory Compliance

- Conduits must comply with BS 7671 wiring regulations and local building codes.

- Always check local depth and rating rules before installation.

What Is the Ideal Burial Depth for Underground Conduits?

Different burial depths suit different applications:

- 15cm (150mm): Suitable for light loads and shallow runs in clay or paved ground.

- 30cm (300mm): Common for domestic installations in back gardens or standard soil.

- 45cm (450mm+): Recommended for detached buildings, commercial installations, or areas prone to excavation.

Ensure all underground conduit runs follow long‑term waterproofing and bedding practices, and backfill with clean granular material to minimise damage.

Source - Electrical Code Coach

What Are the Best Use Cases for Conduits?

Underground conduits serve multiple purposes beyond simple protection:

- They ensure compliance with building safety regulations and help meet RCD/earth bonding requirements.

- They reduce electromagnetic interference, improving signal integrity for data cables.

- They keep wiring organised and accessible, ideal for future replacements, maintenance, or upgrades.

- They prevent damage from chemicals, moisture, rodents, and accidental excavation.

What Is the Difference Between Cable Trunking and Conduits?

Conduits are rigid or flexible pipes designed to carry cable runs and keep them protected, especially outdoors.

Trunking is flat channeling used inside walls or ceilings to organise and protect multiple wires.

While trunking supports internal organisation, conduits provide mechanical protection against harsh outdoor environments, water ingress, and physical impact, making them essential for external installations.

Source - LEARN ELECTRICS

Planning, Trenching & Marking for Safe Installation

Proper planning is the foundation of safe and compliant underground cable work:

Survey and Mapping

Before trenching, identify buried services such as gas, water, or fibre to avoid strikes. Use local utility maps or scan tools to map service locations precisely. Generate a site plan marking all existing buried services.

Marker Tape and Warning Indicators

Place bright-coloured marker tape or tracer wire a short distance above the conduit to signal its location to future excavators. This helps prevent damaging the conduit or cable if digging occurs later.

Trenching Practices

- Trench width should be at least 50mm wider than the conduit to allow bedding material.

- Place a layer of sand or fine soil beneath the conduit before laying it to avoid sharp stone damage.

- Backfill with clean granular material and compact every 150 mm to reduce settlement.

Thermal & Frost Protection

In cold climates, bury conduits below frost lines (often 300–450 mm). Use frost-resistant conduit if cables may be exposed to freeze-thaw cycles.

Access Points & Inspection Chambers

Planning for future access is wise:

- Install inspection chambers or pull boxes at bends or midpoints.

- Leave accessible endpoints above ground or in weatherproof boxes.

- Include sleeves or couplers that allow cable replacement if needed.

These practices aid future maintenance, help detect faults, and simplify upgrades without re-digging.

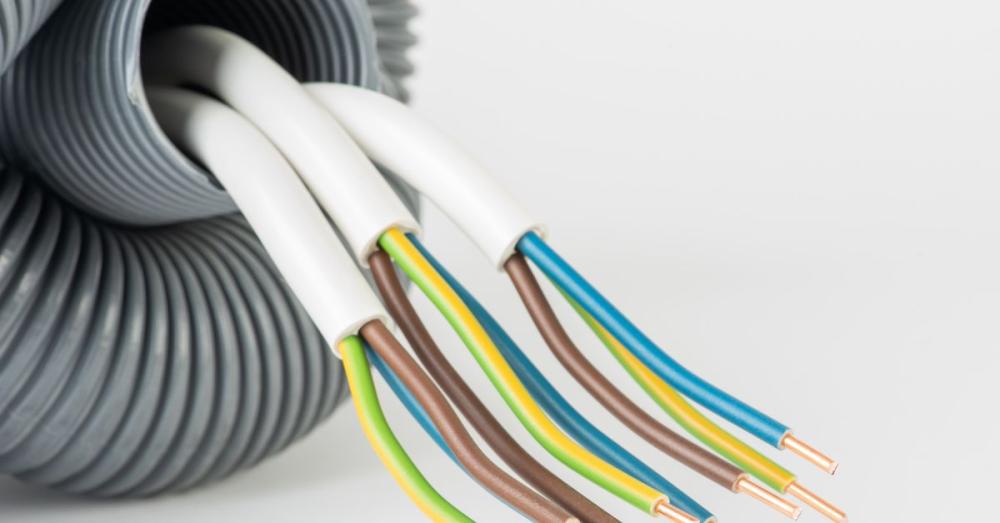

Cable Types for Underground Use

Select cables compatible with your conduit and application:

Armoured or SWA Cable

For high‑risk areas, Steel Wire Armoured (SWA) cable offers mechanical protection and water resistance without conduit. It’s often used in both domestic and industrial settings.

Direct Burial Ratings

Use cable types rated for wet locations, not standard indoor cable. Direct-burial cables often contain full insulation and moisture barriers.

Conductor Material Choice

Choose copper over aluminium for better conductivity and flexibility in bending during pull-ins. Copper also resists corrosion when installed in galv conduit.

Maintenance Best Practices

Underground installations can last decades with minimal care:

- Visually inspect access boxes and junctions annually for water ingress or rodent signs.

- Reconnect clamp screws with proper torque on EMT or metal conduit every few years.

- Use thermal camera or continuity tests to locate faulty cables before digging.

Conclusion

Installing underground electrics ticks all the boxes when it comes to safety, compliance, and future-proofing. By following proper planning, trenching, conduit choice, and cable selection, coupled with post-install inspection practices, you can achieve installations that last and perform reliably.

For high-quality outdoor cable conduit systems, weatherproof accessories, and technical guidance, Meteor Electrical is your dependable partner. We supply full ranges of PVC conduits, galvanised EMT/RMC options, SWA cables, and inspection junction boxes, all aligned with UK standards and ready for UK delivery.

Visit Meteor Electrical to explore our solutions and ensure your outdoor wiring is secure from trench to test.

Stay compliant, stay protected, choose Meteor Electrical.

FAQs

1. What depth should I bury conduit underground?

Conduit burial depth should range between 150 mm and 450 mm, depending on soil type, usage risks, and local code. Marker tape should be placed above to warn future excavators.

2. Can PVC conduit be used without metal armour?

Yes, if the soil is stable. However, using PVC conduit with lower-impact protection may still require mechanical cover where risk is high.

3. Should I use armoured cable instead of conduit?

Yes, SWA cable offers excellent protection for direct burial and is often used in commercial or exposed runs where impact risk is significant.

4. Do I need inspection chambers on straight runs?

Not always, but inspection boxes every 20–30 m or at bends help future access, especially for conduit installations deeper than 300 mm.