What Size of SWA Gland Do You Need? A Complete Guide

What Size of SWA Gland Do You Need? A Complete Guide

When it comes to working with Steel Wire Armoured (SWA) cables, selecting the right gland size isn’t just a matter of preference—it’s vital for safety, durability, and regulatory compliance. At Meteor Electrical, we know how critical this choice can be. That’s why we’ve created this in-depth guide, complete with an easy-to-read SWA gland size chart, to help you make the best decision for your installation.

Whether you’re a certified electrician or a DIYer working on a home project, getting this step right will save time and reduce the risk of failure down the line. Let’s break down everything you need to know.

The Ultimate SWA Gland Size Chart

Our SWA gland size chart is the ideal resource for finding the right gland for any SWA cable and its accessories. Instead of guessing or manually checking specs, our chart simplifies your choice. Use it to find the best SWA gland for outdoor installations, industrial setups, or domestic wiring.

Why Use SWA Glands?

SWA cable glands play a crucial role in protecting your cables and electrical infrastructure. Here’s why they’re a non-negotiable part of professional installations:

1. Secure Cable Ends

Cable ends are prone to movement and stress. SWA glands hold cables securely, reducing the risk of disconnections, which can lead to short circuits or system failure.

2. Provide Earthing

Proper grounding is critical to safety. These glands support the cable’s earthing system, helping prevent electric shocks and system damage (Electrical Safety First).

3. Ensure Effective Insulation

SWA glands help maintain insulation, preventing faults and protecting nearby components. This is particularly useful in complex setups with multiple cables.

4. Offer Bonding and Strain Relief

They provide both bonding and mechanical strain relief, ensuring that your cable remains intact and functions optimally even in high-vibration or load-heavy areas (source).

5. Seal Against Environmental Hazards

Cables in outdoor or industrial environments face constant threats from dust, moisture, and chemicals. SWA glands provide an IP-rated seal to shield against these hazards.

6. Support Multiple Applications

From commercial buildings to outdoor lighting setups, SWA glands are adaptable to various uses. They're a go-to choice for installers dealing with challenging conditions.

Credit- GSH Electrical

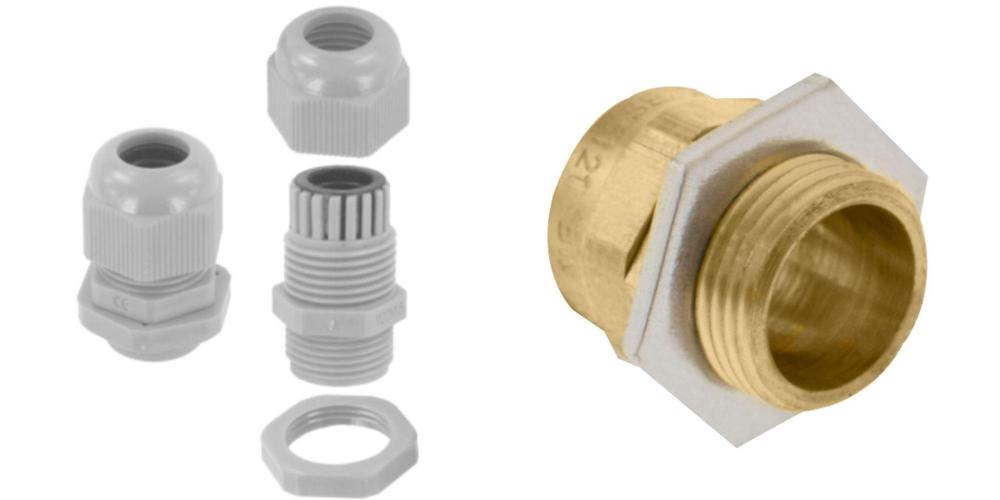

Choosing the Right Materials for Your SWA Glands

Material choice directly affects performance and life span. Here are the most common materials used:

Metallic Glands

- Brass: High mechanical strength and corrosion resistance; ideal for indoor and general industrial use.

- Stainless Steel: Excellent for marine and chemical environments due to its rust-proof nature.

- Aluminium: Lightweight and corrosion-resistant, suitable for portable or ceiling-mounted setups.

Non-Metallic Glands

- Nylon: Durable, weather-resistant, and non-conductive. Great for outdoor or damp environments.

- PVC: Lightweight and affordable, suitable for low-risk indoor applications.

- PTFE (Teflon): Resilient to high temperatures and aggressive chemicals; ideal for scientific and specialised use.

Combination Glands

Some glands use a mix of materials to provide flexibility, increased protection, and improved mechanical strength—perfect for industrial SWA gland installations.

Corrosion Resistance

Always consider your working environment. For example, stainless steel glands are best for marine or corrosive chemical areas due to their excellent saltwater resistance.

Understanding How SWA Cable Glands Work

SWA cable glands are built for function and protection. They usually include:

- Lock nuts

- Sealing washers

- Compression nuts

- Armour clamps

- Rubber or polymer seals

Advanced versions may include double compression seals and dual protection zones for use in high-risk or explosive environments.

The glands work by anchoring the cable, forming a tight environmental seal, and maintaining strain relief. This reduces cable movement, prevents moisture ingress, and protects from stress or mechanical damage.

Choosing the Right SWA Gland Size

Here’s what you need to know when selecting the correct gland size for your SWA cable:

1. Measure Cable Diameter

Start with the outer sheath diameter and inner bedding size. Use a digital calliper for precise readings.

2. Construction and Core Count

Larger or multi-core cables may require specific gland types and sizes. Our chart accommodates cables from 1-core to 48-core.

3. Armour Braid Type

Identify whether your cable uses aluminium or steel braid. Armour size and type impact the gland's compatibility.

4. Pressure and IP Ratings

Ensure the gland meets required IP rating and pressure standards for your project.

Ask These Questions:

- Does the gland fit the cable and housing?

- Is the pressure rating high enough?

- Do you need stopper plugs or shrouds for added sealing?

- Does it offer effective earthing?

Specialised SWA Glands: 20S and M20 Variants

At Meteor Electrical, we offer specific options tailored for special applications:

- 20S SWA Cable Gland: Designed for environmental sealing and mechanical retention, ideal for compact installations.

- M20 and M20S Glands: Known for their silica gel sealant, M20 variants provide thermal stability and high-temperature resistance for energy systems.

These options are perfect for high-performance or temperature-sensitive projects.

Credit - tvtradedave

Secure Your Connections with Meteor Electrical

We understand that finding the right product shouldn't be a hassle. That’s why at Meteor Electrical, we provide a comprehensive range of:

- SWA glands in various sizes and materials

- Armoured cables

- Installation accessories

- Earth kits and shrouds

Whether you need a solution for a residential, commercial, or heavy industrial setting, you can rely on us for quality, speed, and service.

Visit Meteor Electrical to explore our full catalogue and benefit from competitive pricing and next-day delivery across the UK and Ireland.

Conclusion

Choosing the correct SWA gland size may seem technical, but with the right guidance and tools, it’s straightforward. A secure connection ensures your installation is safe, efficient, and durable. By using the SWA gland size chart and understanding your cable’s dimensions and environment, you can make the right decision every time.

At Meteor Electrical, we’re proud to supply premium-quality SWA cable glands and accessories tailored for real-world installations. Explore our range today and experience the perfect blend of reliability and performance.

Frequently Asked Questions (FAQs)

1. What is an SWA cable gland used for?

An SWA cable gland is used to securely terminate Steel Wire Armoured (SWA) cables, providing mechanical strain relief, earthing, and environmental protection. These glands prevent moisture and dust ingress, ensuring safe and durable electrical installations, especially in outdoor or industrial environments.

2. How do I choose the correct size for an SWA gland?

To select the correct SWA gland size, measure the outer diameter of the cable bedding, check the armour type, and ensure it matches the short-circuit fault rating. For accurate sizing, use a detailed SWA gland size chart like the one provided by Meteor Electrical.

3. What materials are SWA cable glands made from?

SWA glands are available in materials such as brass, stainless steel, aluminium, nylon, PVC, and PTFE (Teflon). Your choice depends on the installation environment—for example, stainless steel for corrosion resistance in marine settings or nylon for lightweight durability in industrial setups.

4. Can SWA cable glands be used outdoors?

Yes, SWA cable glands are ideal for outdoor use. They offer IP-rated protection against water, dust, and chemicals, making them suitable for harsh environments. Always choose glands with proper weatherproof sealing for external electrical installations.

5. Are there different types of SWA glands for various applications?

Yes, there are multiple types of SWA cable glands designed for specific tasks. For example, 20S glands offer compact mechanical retention, while M20 glands with silica gel seals are ideal for high-temperature applications. Select the type based on your cable size, load rating, and environment.