Choosing The Right Cable for Your Electrical Project

Choosing The Right Cable for Your Electrical Project

Selecting the right electrical cable is the foundation of a safe, efficient, and long-lasting installation. The wrong cable can overheat, trip circuits, damage equipment, and create safety hazards. The right one improves performance, reduces maintenance, and passes inspection with ease. This guide walks through wiring basics, cable vs wire differences, key selection factors (location, construction, insulation, sizing), and the most common UK domestic cable types, plus modern color coding, connection methods, and trunking.

For reference, always consult the IET’s BS 7671 wiring regulations overview and, for project planning, the Energy Saving Trust. For quick specification and sourcing, see Meteor Electrical’s cable range.

Understanding Electrical Wiring

Successful projects start with identifying the correct wiring, how it’s installed, and how it’s protected. This means understanding conductors and insulation, protective devices (MCBs, RCDs, RCBOs), and UK electrical codes. For residential work, compliance with current wiring practice (BS 7671) safeguards safety and reliability. Start by mapping circuits, anticipating loads, noting environmental conditions, and any special classifications (e.g., bathrooms, outdoors). With these clear, cable selection becomes systematic—not guesswork.

What Is The Difference Between Electrical Wires and Cables?

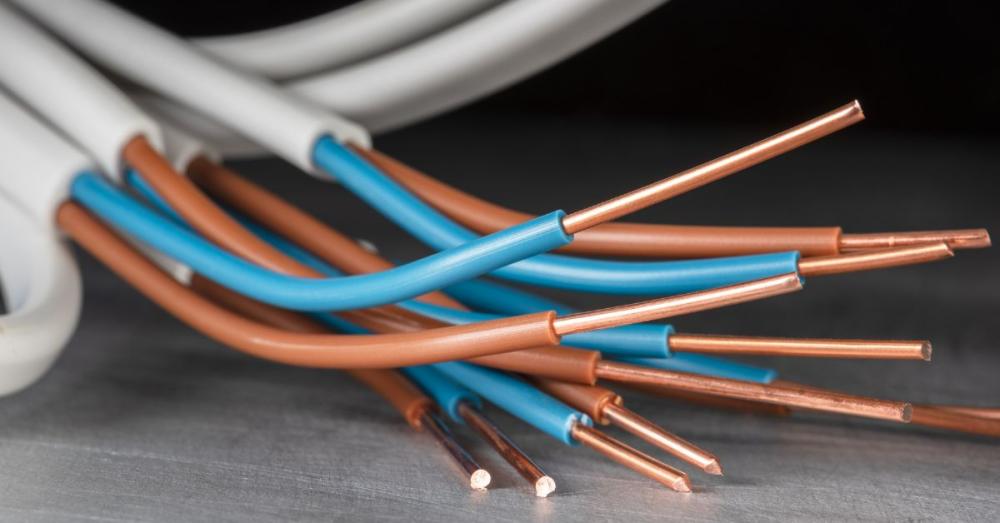

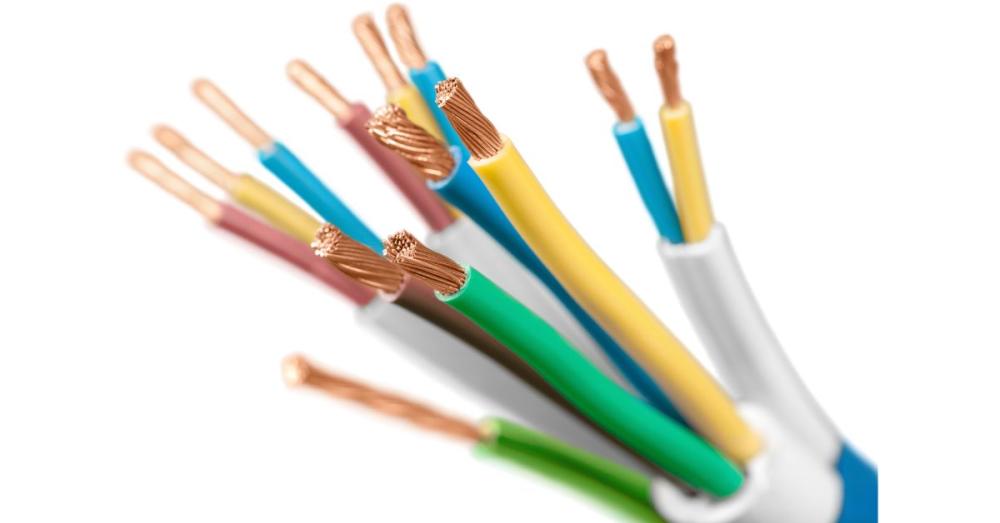

A wire is the conductive core (solid or stranded), while a cable is one or more conductors bundled with insulation and, often, a protective sheath. The sheath protects against abrasion, moisture, chemicals, UV, or impact. Armoured and fire-resistant constructions add extra layers for demanding environments.

- Armoured cables for underground or external runs where mechanical protection is essential.

- Fire-resistant cables: Made to maintain critical circuits during a fire. See below for where and why to use them.

Solid and Stranded Wiring

- Solid conductor (single-strand) is robust and easy to terminate, ideal for fixed domestic wiring in walls and ceilings; less flexible for frequent bending.

See single-strand wire. - Stranded conductor uses multiple fine strands for flexibility, perfect for movement, vibration, or tight bends (e.g., lighting tracks, control panels, appliance tails).

Tips on Finding The Right Cable

Installation Location

The environment dictates sheath choice. UV/weather resistance, temperature, mechanical protection, and even the need for low smoke zero halogen (LSZH) cable in certain applications. Pulling tension, sharp bends, and abrasive edges can damage insulation, plan cable routes, support spacing, and bending radii. Outdoor and underground runs benefit from armoured SWA or direct-burial-rated cables, drip loops, and proper termination glands.

The Cable’s Construction

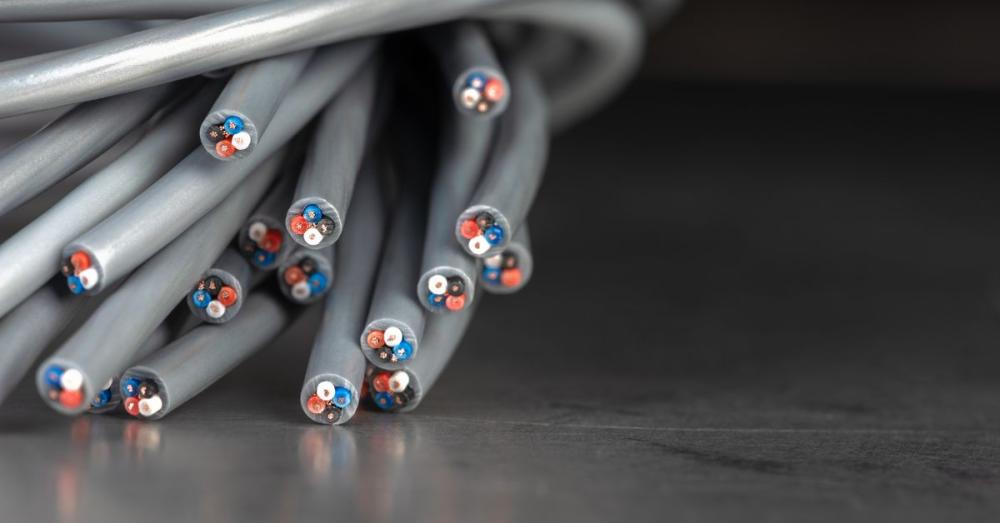

Focus on two internal design aspects: conductor arrangement and insulation system.

- Cable arrangement: Single-core vs. multi-core, with or without CPC (earth). Three-core with CPC offers phase versatility (e.g., two-way switching) and a dedicated earth.

- Insulation covering: PVC, LSZH, XLPE, and rubber compounds each suit different temperatures, chemical exposure, and fire/smoke requirements. Bathrooms, kitchens, garages, plant rooms, or external runs often need elevated ingress and thermal performance. Check the cable’s operating temperature, derating factors, and installation method.

Determine The Cable Size

Cable sizing must consider:

- Current-carrying capacity (Iz) relative to design current (Ib), protective device (In), and installation method/derating factors.

- Voltage drop over the run length to keep loads within tolerance.

- Short-circuit rating to ensure the cable survives fault conditions until protection operates.

Ignoring voltage drop or short-circuit capacity risks nuisance trips, brown-outs, or equipment damage. When unsure, upsize one step or shorten the run.

For easy calculations, use a cable voltage drop calculator like those from Eland Cables or Cable-World.

Domestic Cables Used In The UK

Twin Core and Earth Cables

The staple for domestic circuits: two insulated conductors (brown live, blue neutral) plus a bare CPC (earth) that must be sleeved green/yellow at terminations. See twin & earth cable.

3-Core and Earth Cables

Ideal for two-way lighting circuits and applications needing an extra core (e.g., switched lives). See 3-core & earth.

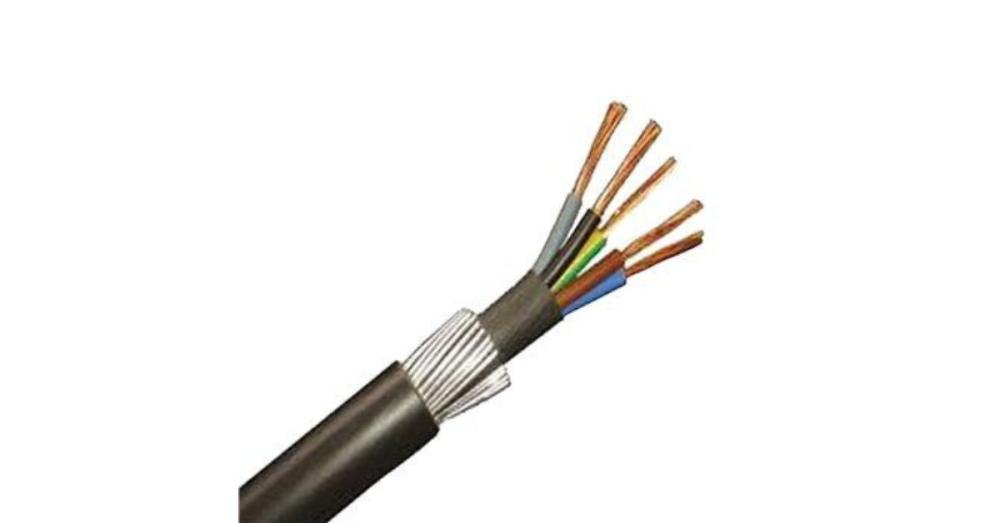

Armoured Cables (SWA)

Steel Wire Armoured (SWA) for underground feeds, outdoor lighting, outbuildings, EV chargers, and long external runs. Always terminate with proper glands, bond the armour, and earth at the supply end. See armoured cables.

Communication Cables

Low-voltage, low-current data and signal cables for Ethernet, telephony, alarms, and controls. See communication cables. Keep data and power separated or appropriately shielded to prevent interference.

Direct Burial Cable

For underground runs without conduit (subject to local codes), choose cable with a suitable sheath and moisture barrier. Use sand bedding and warning tape as good practice, even when direct burial is permitted.

Fire-resistant Cables

Maintain power to emergency systems (alarms, emergency lighting, voice alarms) during a fire. Typically built with mica/glass tape over conductors and LSZH sheaths to minimise smoke/toxic emissions. See fire-resistant cables.

Source - eFIXX

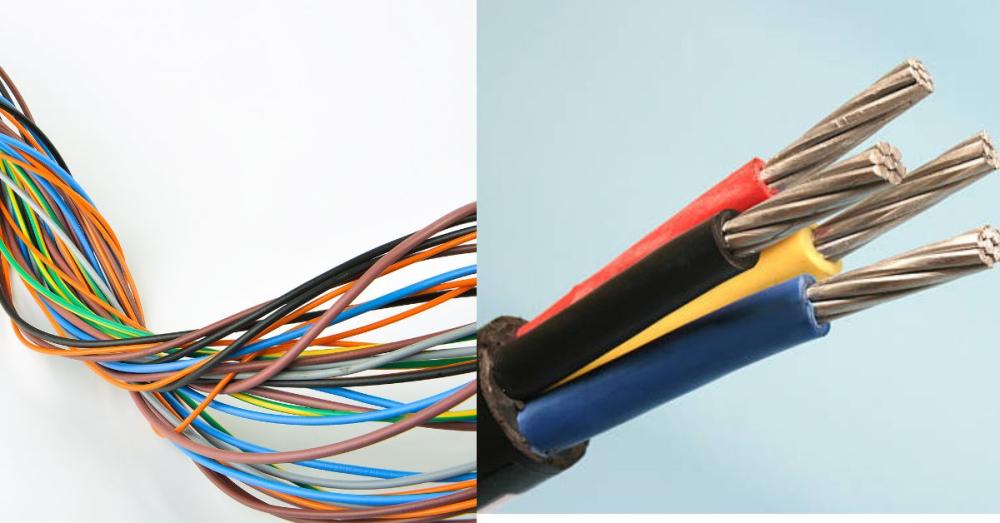

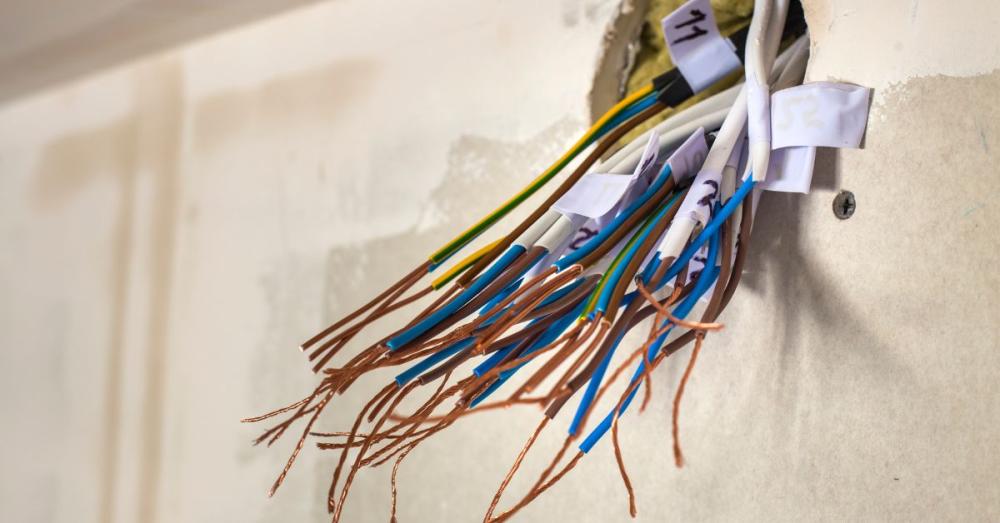

What Is Electrical Wire Colour Coding?

Modern UK and Ireland conductor colors align with harmonised EU standards:

- Green/Yellow: Earth (CPC)

- Brown: Live

- Blue: Neutral

Consistency makes troubleshooting safer and faster. Colour applies to inner cores and often to sheaths for quick circuit identification. For UK color guidance, see RS Components wiring colour guide.

What Are The Old Wire Colours In The UK?

Pre-2004/2006 systems used:

- Earth: Green/yellow (sometimes bare CPC, sleeving required)

- Live: Red

- Neutral: Black

The 17th Edition adoption harmonised colors to brown/blue for phase/neutral; older installations still exist, always verify colors at source and label clearly when extending circuits. For regulatory context, see the IET’s BS 7671 wiring regulations.

What Are Electrical Wiring Connections?

Single-Phase Wiring

Standard domestic supply arrangement, typically 230 V AC. Circuits include earth, live, neutral, and protective devices matched to cable size and application.

Three-Phase Wiring

For heavier loads (e.g., workshops, lifts, HVAC), three live phases share load with smoother delivery. Commonly 400/415 V line-to-line; neutral may be omitted. Ensure correct protective coordination and suitable cable size for higher fault levels.

Do You Need Trunking for Electrical Wiring?

Metal trunking protects and organises cables, supports segregation (power vs. data), and helps contain fire spread. It simplifies future additions and maintenance. See galvanised steel trunking for neat, code-compliant, accessible routes.

How to Choose the Right Cable for Your Electrical Project

Step 1: Define Load and Circuit

- Appliance/load type, design current, duty cycle

- Supply (single vs. three-phase), protective device, RCD/RCBO requirements

Step 2: Map the Route and Environment

- Length, bends, grouping, ambient temperature, installation method

- Indoor vs outdoor, UV, moisture, mechanical risk, rodents, chemicals

Step 3: Select Construction and Insulation

- Conductor type (solid vs stranded) and core count

- Insulation (PVC/XLPE/LSZH/rubber) and sheath (UV, oil, abrasion resistance)

Step 4: Size the Cable

- Current capacity, derating, voltage drop, short-circuit withstand

- Upsize for headroom or long runs

Step 5: Specify Accessories

- Glands, cleats/clips, trunking/tray, junction boxes, terminations, labels

- Surge protection (where required), IP ratings, and suitable enclosures

Step 6: Document and Test

- Label circuits, update schedules

- Keep test results (insulation resistance, earth continuity, RCD trip times, Zs/Ze) for traceability and future maintenance

High-Authority Resources (for deeper reading)

- BS 7671 overview (IET Wiring Regulations): BS 7671

- Wiring colours practical guide: UK wiring colours

- UK power networks safety and responsibilities: National Grid

- Cable size calculator: Eland Cables

Conclusion

Selecting the right cable is a safety, performance, and cost decision. Start with load and route, choose the right construction and insulation for the environment, and size for current, voltage drop, and fault survival.

For outdoor and underground feeds, armoured SWA is often the most robust choice; for critical circuits, specify fire-resistant LSZH to maintain life safety systems; and for general domestic wiring, choose UK twin and earth cable sizes appropriate to the circuit and installation method. If in doubt, upsize one step or shorten the run and keep documentation tidy for future maintenance.

Ready to specify with confidence?

Explore a full range of domestic and commercial cabling, glands, trunking, enclosures, and accessories at Meteor Electrical.

FAQs

1. What cable is best for outdoor power to a shed?

An SWA cable is typically the best armoured cable for outdoor power—its mechanical protection withstands weather and abrasion; size it for current, voltage drop, and route length.

2. What size twin & earth do I need for domestic sockets and lights?

Common UK twin and earth cable sizes are 1.0–1.5 mm² for lighting and 2.5 mm² for ring final circuits; always confirm by load, route, protection, and voltage drop.

3. When should I specify LSZH or fire-resistant cable?

Use low smoke zero halogen LSZH cable in people-dense or escape routes, and fire resistant electrical cable for emergency systems like alarms and emergency lighting.

4. Can I bury electrical cable directly in the ground?

Yes. Use direct burial electrical cable UK rated for underground installation (often SWA), laid in sand with warning tape, and terminated with proper glands.

5. How do I prevent voltage drop on long cable runs?

Increase cable size, shorten routes, reduce load, or raise circuit voltage (where applicable). A cable voltage drop calculator helps verify compliance before install.