Cable Conduit

When it comes to ensuring the safety and longevity of your electrical installations, choosing the right cable conduit is crucial. Cable conduits, whether metal or plastic, are the backbone of electrical wiring protection, particularly in commercial and industrial settings. Did you know that according to the National Electrical Code (NEC), over 50% of electrical fires are preventable with the correct installation of conduits?

In this comprehensive guide, we’ll dive into everything you need to know about cable conduits—from what they are, to how to choose the right one for your project and the critical considerations to keep in mind during installation. Whether you're an experienced electrician or a DIY enthusiast, this guide will help you make informed decisions to keep your electrical systems safe and efficient.

What Is A Cable Conduit?

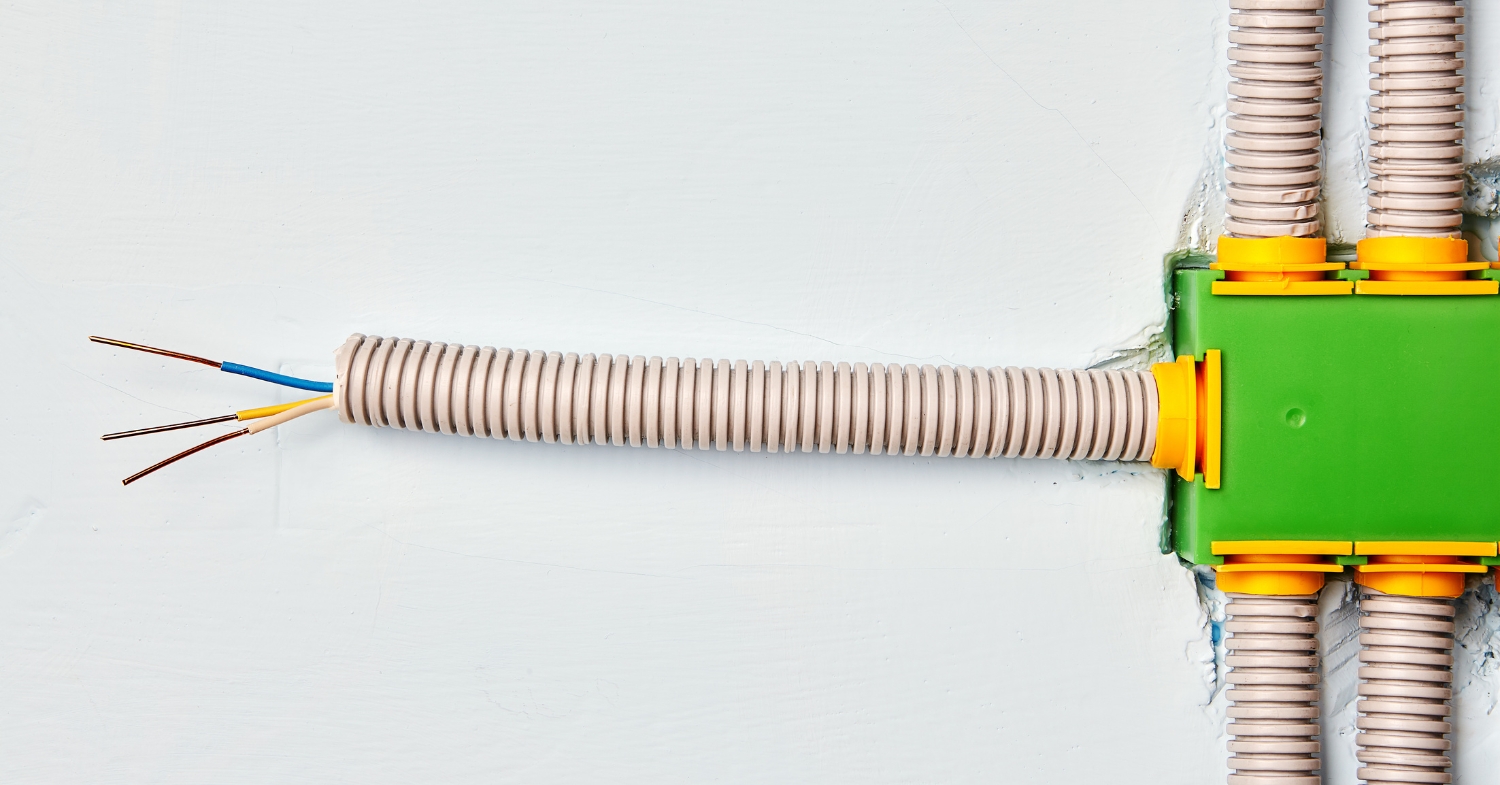

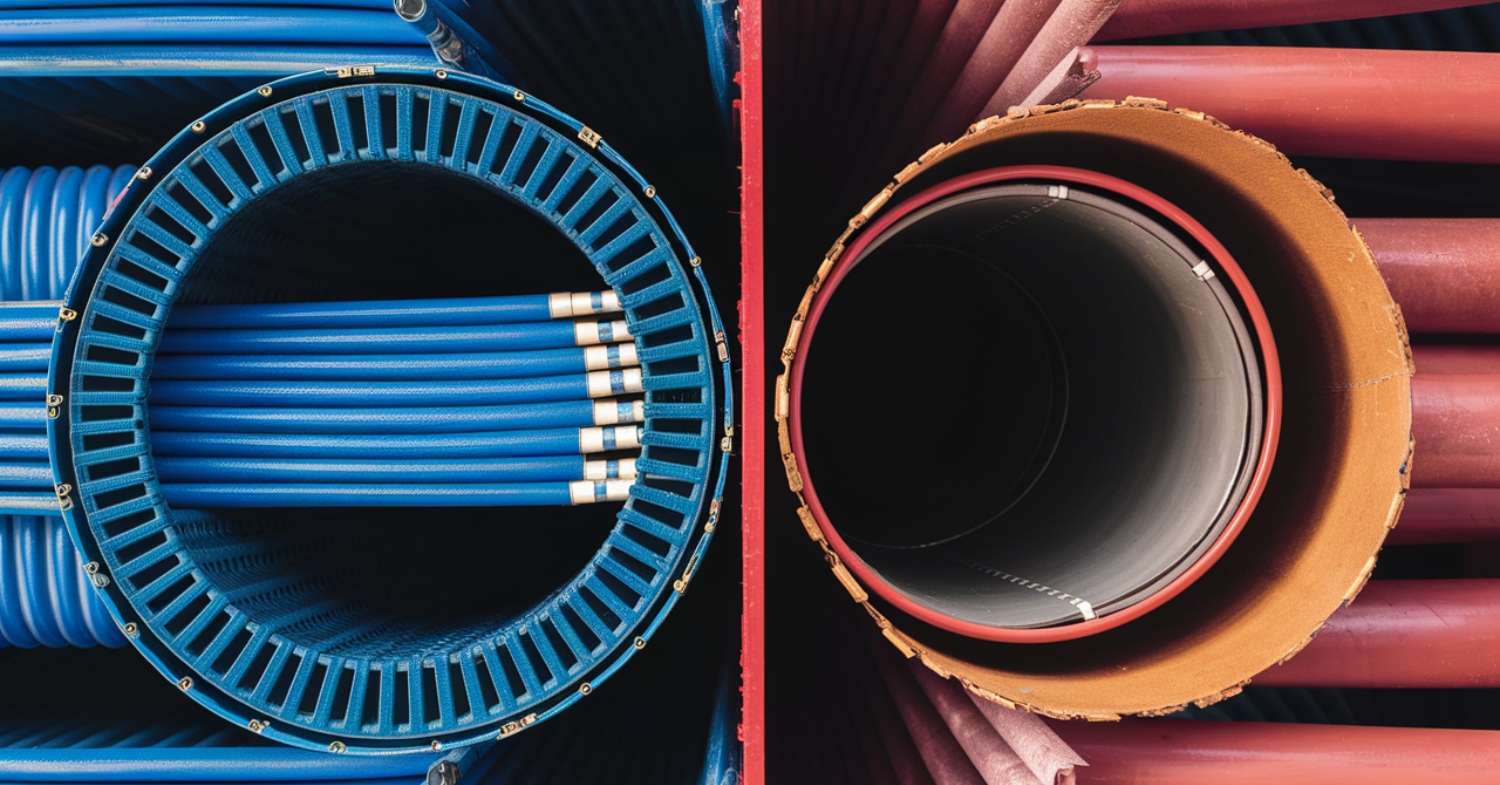

At its core, a cable conduit (also known as an electrical conduit) is a tube-like structure designed to house and protect electrical wiring. These conduits can be made from a variety of materials, including metal, plastic, and even fired clay, each offering unique benefits depending on the installation environment.

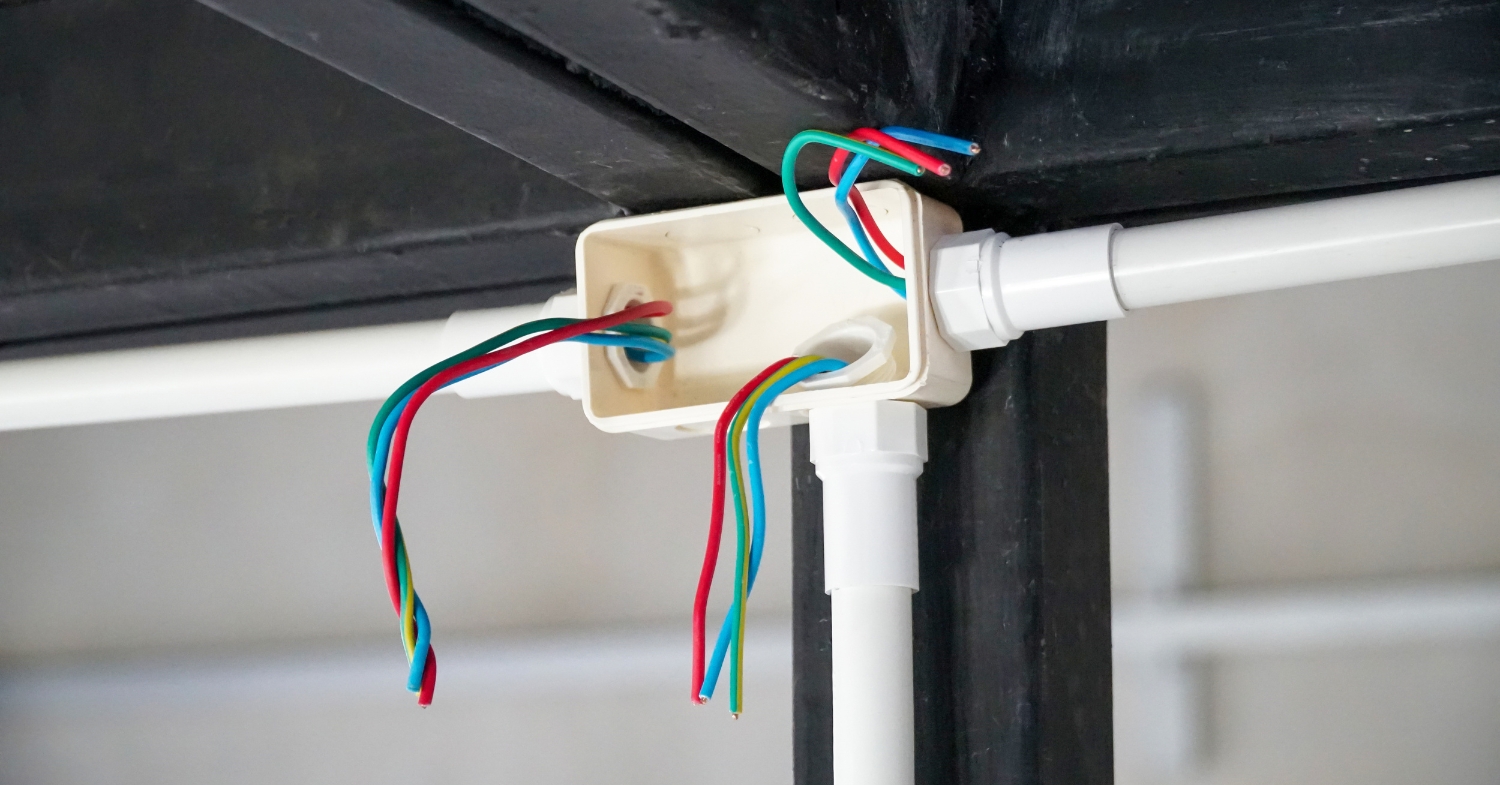

Rigid vs. Flexible: Cable conduits come in both rigid and flexible forms, allowing for versatility in different installation settings. Rigid conduits are often used in environments where the wiring needs to be protected from external impacts, while flexible conduits are ideal for areas where the wiring might need to navigate around corners or other obstacles.

Protective Function: The primary purpose of a conduit is to shield wires from potential hazards such as moisture, chemical exposure, and physical damage. They are especially useful in unfinished spaces like basements, attics, and even outdoor settings, where wires are more susceptible to damage.

Diverse Materials: While metallic conduits are the most common, particularly in commercial and industrial settings, conduits made from plastic, fibre, and fired clay are also widely used. The choice of material often depends on factors such as the environment, cost, and specific project requirements.

Credit: RSP Supply

Why Are Cable Conduits Essential?

Cable conduits offer more than just protection for your electrical wiring. They are crucial for ensuring that your installation meets safety standards and remains functional over time. Here are a few reasons why cable conduits are indispensable:

- Meeting Codes and Regulations: In many regions, building codes require the use of conduits for certain types of installations. For instance, in areas prone to moisture or chemical exposure, conduits are often mandatory to prevent potential electrical hazards.

- Versatility in Design: Cable conduits can be customised to fit any installation layout, whether it's a simple residential setup or a complex industrial system. This flexibility allows electricians to route wires safely and efficiently, even in challenging environments.

- Protection from Damage: One key benefit of using cable conduits is the additional layer of protection they provide. Whether safeguarding wires from moisture, fire, or physical impacts, conduits help ensure that your electrical system remains intact and functional.

- Reducing Interference: Metal conduits, in particular, can help reduce electromagnetic interference (EMI), which is crucial in environments with sensitive electronic equipment. By minimising EMI, conduits ensure that your wiring performs optimally.

- Organising Wiring: In complex installations with multiple wires, conduits help keep everything organised. This not only makes the system easier to manage but also reduces the risk of damage to the wiring during maintenance or upgrades.

Types of Cable Conduits

Cable conduits come in various forms, each designed to meet specific installation needs. Below are some of the most commonly used types:

| Type of Cable Conduit | Material | Flexibility | Ideal Use | Key Benefits |

|---|---|---|---|---|

| Electrical Metal Conduit (EMT) | Galvanised Steel | Rigid (can be bent) | Indoor residential and light commercial installations | Durable, easy to shape, good protection |

| Electrical Non-Metallic Conduit (ENT) | Plastic (PVC) | Flexible | Residential walls, concrete structures | Fire and moisture-resistant, easy to install |

| Flexible Metal Conduit (FMT) | Spiral Metal Tubing | Highly Flexible | Short runs, water heaters, AC units | Easy to install in tight spaces, flexible |

| Non-Metallic Liquid-Tight Flexible Conduit (NLFC) | PVC with rigid PVC reinforcements | Flexible | Moist or oily environments, pools, HVAC systems | Watertight, flame-resistant, durable |

| Rigid Metal Conduit (RMC) | Galvanised Steel | Rigid | Structural piping, utility service lines | Heavy-duty, corrosion-resistant |

Electrical Metal Conduit (EMT)

Electrical Metal Conduits (EMTs) are among the most popular choices for rigid conduit systems. Made from galvanised steel, EMTs are lightweight yet durable, offering a non-flexible solution that can be bent into shape with a conduit bender. EMTs are ideal for indoor residential and light commercial installations but are not recommended for areas prone to severe physical damage or corrosive environments. For outdoor installations, watertight fittings are necessary to protect against moisture.

Electrical Non-Metallic Conduit (ENT)

For those seeking flexibility, Electrical Non-Metallic Conduits (ENTs) are an excellent choice. Made from pliable plastic, ENTs are designed for installation within walls and concrete structures, providing excellent protection against fire and moisture. However, they are not suitable for exposed or outdoor locations where they might be subject to weather or other external factors.

Flexible Metal Conduit (FMT)

Flexible Metal Conduits (FMTs) are known for their spiral shape, making them easy to bend and install in tight or awkward spaces. FMTs are commonly used in short-run installations, such as connecting water heaters or air conditioning units. Some FMTs, known as Liquid-Tight Flexible Metal Conduits (LFMCs), come with a plastic outer sheath that makes them watertight, ideal for outdoor applications.

Non-Metallic Liquid-Tight Flexible Conduit (NLFC)

NLFCs are typically used as a more flexible alternative to metal conduits. These conduits feature a PVC coating that provides watertight protection, making them suitable for use in moist or oily environments. NLFCs are also flame-resistant and can be used in both indoor and outdoor installations, particularly in commercial and industrial settings.

Rigid Metal Conduit (RMC)

Rigid Metal Conduits (RMCs) are made from heavy-duty materials like galvanised steel, offering robust protection for electrical wiring. RMCs are typically used for structural piping in homes and are joined with threaded connections to ensure a secure fit. These conduits are ideal for utility service lines and other applications where durability is paramount.

What Type of Wiring Works Best with Cable Conduits?

Cable conduits are designed to accommodate a wide range of wiring types, but they work particularly well with THWN and THHN wires.

- THWN Wires: These wires feature thermoplastic insulation and are resistant to both heat and water, making them ideal for use in wet or outdoor environments.

- THHN Wires: Similar to THWN wires, THHN wires offer high heat resistance and often come with a nylon coating for added durability. These wires are commonly used in residential and commercial installations.

When using non-metallic cables, a grounding wire is essential. However, metal conduits can sometimes serve as the grounding pathway, eliminating the need for a separate grounding wire.

Credit: Practical Home Projects

How to Run Wires Through Cable Conduits?

Running wires through a conduit might seem straightforward, but it can be tricky, especially in long or complex installations. Here are some tips to make the process smoother:

- Use the Old Wire: If you're upgrading or replacing wiring, attach the new wire to the old one and pull it through the conduit. This method works well for simple installations but might not be ideal for longer runs or damaged conduits.

- Pulling Techniques: For new installations, use a fish tape to guide the wire through the conduit. If the wire gets stuck, applying a lubricant designed for electrical wires can help reduce friction and make the process easier.

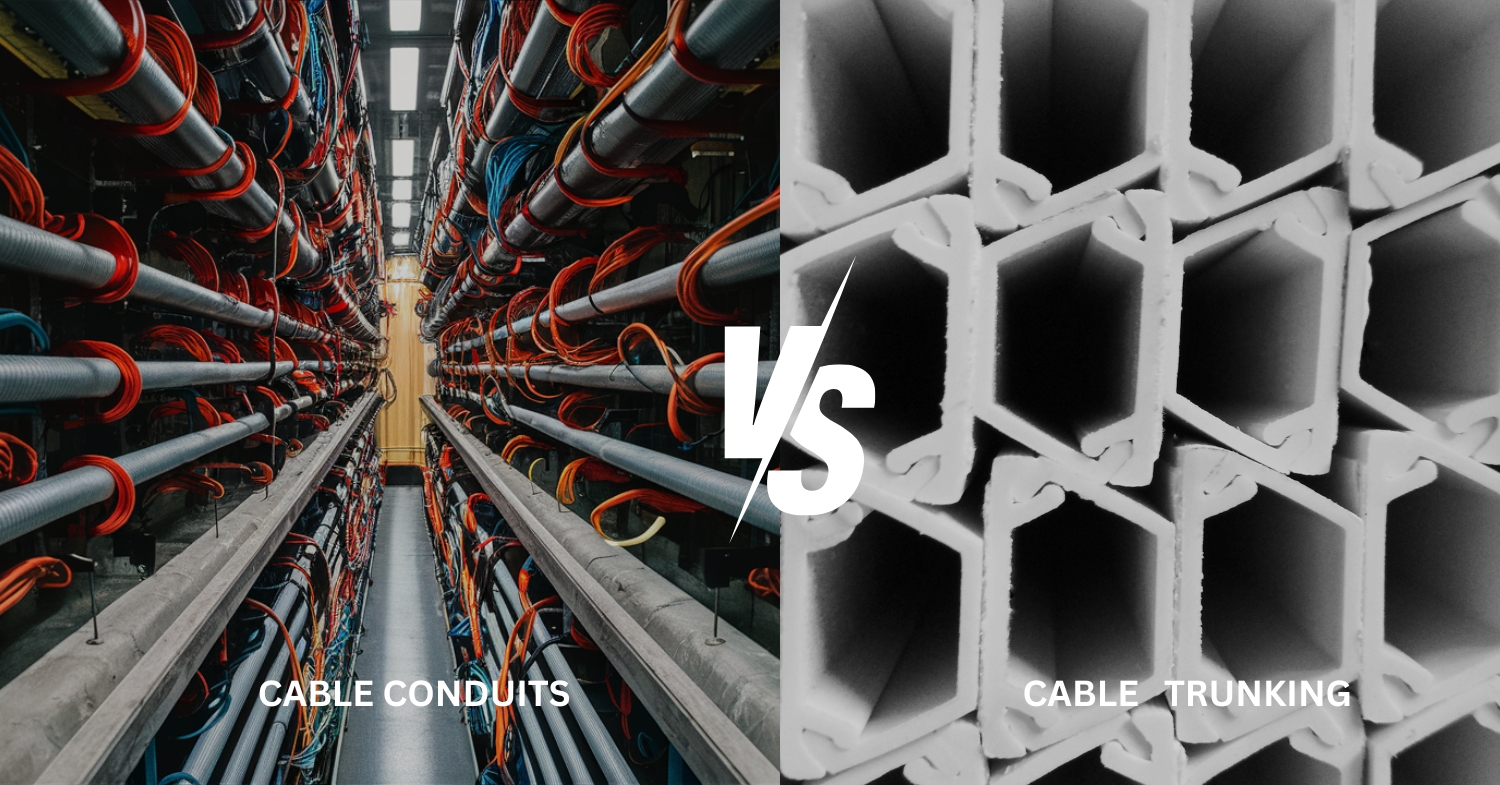

Cable Trunking vs. Cable Conduits: What’s the Difference?

While cable trunking and conduits both serve to protect and organise electrical wiring, they have distinct applications:

- Cable Trunking: Typically used to organise and conceal multiple cables in a building, trunking systems are ideal for managing large volumes of wiring. They are often installed behind walls and are more suitable for environments with low physical risks.

- Cable Conduits: Conduits, on the other hand, are used to protect specific wires or groups of wires, especially in environments where they might be exposed to hazards like moisture or chemicals. Metal conduits also help reduce electromagnetic interference, making them a better choice for sensitive installations.

=> Electrical Cable Buy Online

How to Choose the Right Cable Conduit?

Choosing the right cable conduit for your project depends on several factors:

- Installation Requirements: Consider where and how the conduit will be installed. Will it need to bend around corners, be buried underground, or be placed within concrete? Ensure the conduit you choose is rated for these specific conditions.

- Cost Considerations: Budget is always a factor in construction projects. While some conduit types may be more expensive due to their materials or installation requirements, it's important to weigh these costs against the benefits they provide, such as durability and protection.

- Potential Hazards: Assess the environment in which the conduit will be installed. Will it be exposed to moisture, chemicals, or physical impacts? Choose a conduit that offers the appropriate level of protection for these hazards.

- Compliance with Regulations: Ensure that the conduit type you choose meets all local building codes and safety regulations. Non-compliance can lead to costly repairs and even pose safety risks.

Conclusion: Why Choose Meteor Electrical for Your Cable Conduit Needs?

Finding the right cable conduit can be a daunting task, given the variety of options available. At Meteor Electrical, we offer a comprehensive range of high-quality cable conduits to meet all your installation needs. Whether you're looking for durable metal conduits for industrial applications or flexible plastic conduits for residential projects, our extensive selection ensures that you'll find the perfect solution.

Our products are designed to meet the highest safety standards, offering reliable protection for your wiring in any environment. Visit Meteor Electrical today to browse our full range of cable management systems and find the right conduit for your next project.

FAQs

1. What is the primary purpose of a cable conduit?

The primary purpose of a cable conduit is to protect electrical wiring from physical damage, moisture, chemicals, and electromagnetic interference, ensuring safety and longevity in various installation environments.

2. How do I choose the right type of cable conduit for my project?

Choose the right conduit by considering the installation environment, potential hazards, material durability, flexibility needs, and compliance with local safety regulations. Match the conduit type to the specific requirements of your project.

3. Can I use metal conduits in outdoor installations?

Yes, metal conduits can be used outdoors, but they must be paired with watertight fittings and corrosion-resistant materials to withstand moisture and environmental exposure.

4. What types of wires are best suited for use in cable conduits?

THWN and THHN wires are commonly used in cable conduits due to their heat—and water-resistant properties, which make them ideal for both residential and commercial installations.

5. How do cable conduits differ from cable trunking?

Cable conduits protect individual or small groups of wires, often in exposed or hazardous environments. Cable trunking, on the other hand, organises and conceals multiple cables, typically in low-risk indoor settings.