PVC Cable Conduit Guide: Sizes, Uses, Fittings | Meteor Electrical

PVC Cable Conduit Guide: Sizes, Uses, Fittings | Meteor Electrical

Choosing the right plastic cable conduit is about more than just checking a box for compliance, it’s the backbone of a safe, organized, and future-proof electrical installation. At Meteor Electrical, we specialize in robust, UV‑stabilized PVC cable conduit systems and fittings that simplify installation, protect wiring in harsh environments, and align with best practices from trusted sources like the NFPA 70 (NEC) and the Electrical Safety Foundation International.

This definitive guide covers everything you need to know about plastic conduit: what it is, where it excels, how to choose the right size and type, essential fittings, practical installation tips, and links to high-authority references for deeper reading.

What Are Plastic Cable Conduits?

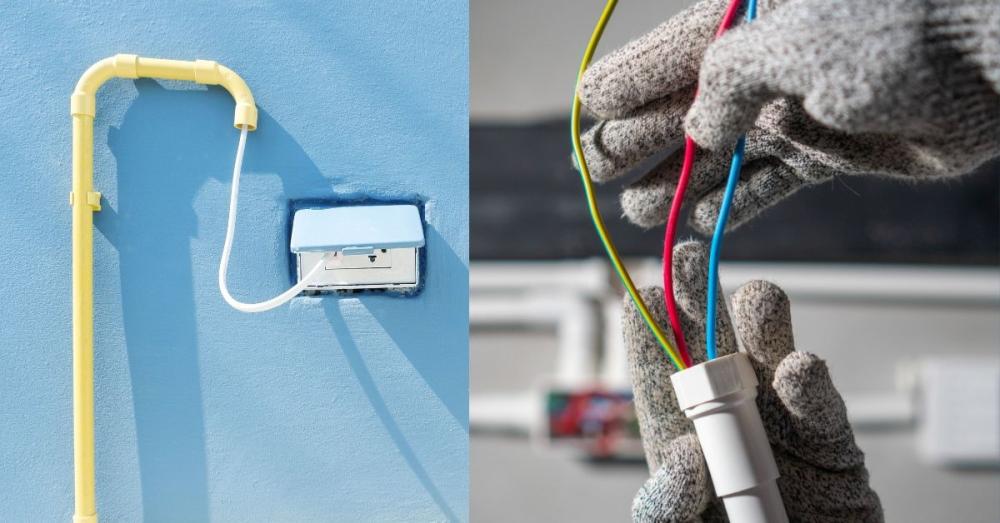

PVC (polyvinyl chloride) cable conduits are nonmetallic raceways designed to protect and route electrical wiring, offering insulation, moisture resistance, and corrosion protection for residential, commercial, and industrial projects. By shielding conductors from physical damage and environmental exposure, PVC electrical conduit for outdoor use helps maintain safe operating temperatures and electrical integrity in diverse settings. These systems are valued for their durability, impact resistance, and compatibility with common building wires such as THHN and THWN.

PVC conduit comes in both rigid and flexible forms, available in trade sizes from 1/2 inch up to 6 inches, with clear markings to indicate suitability for indoor, outdoor, underground, or corrosive locations. Proper identification, such as “Sunlight Resistant” for exterior runs is key to compliant, long-lasting installations.

What Is The Best Cable Conduit Plastic?

With so many options on the market, the “best” conduit depends on your specific environment, routing needs, and compliance requirements. Meteor Electrical offers a curated selection of PVC conduits that balance flexibility, UV stability, temperature tolerance, and ease of installation, ideal for both new builds and upgrades.

Decoduct 32mm Flexible PVC Conduit

If your project demands bendability around tight corners or through congested spaces, the Decoduct 32mm flexible PVC conduit is an excellent choice. Its smooth, flexible design simplifies installation and reduces the need for excessive fittings. When specified as “Sunlight Resistant,” it’s perfect for PVC electrical conduit for outdoor use, resisting UV degradation that standard plumbing PVC cannot handle. This makes it a reliable option for rooftop, façade, and other weather-exposed installations.

Cablecraft’s Betaflex 25mm PVC Conduit

For environments where fire safety is a priority, Cablecraft’s Betaflex 25mm conduit offers superior flame retardance and low smoke/halogen-free properties. These features make it ideal for commercial, industrial, and public spaces where hazard mitigation is critical. Its flexibility and accessory compatibility ensure clean, efficient installations for branch runs and device drops.

Browse Meteor Electrical’s full range to find the perfect conduit for your project’s demands, environment, and code requirements.

What Are Plastic Cable Conduits Used For?

Meet Codes and Regulations

PVC conduit is often required or preferred by electrical codes for its nonmetallic, corrosion-resistant properties. It provides secure routing, protection from physical damage, and clear identification, key factors in passing inspections and ensuring long-term reliability. Always align your conduit and fittings with NFPA 70 (NEC) standards, available at NFPA.org.

Protect Wiring From Damage

Conduit shields conductors from impact, abrasion, moisture, and chemicals while maintaining proper bend radii to prevent insulation damage. For exterior installations, UV‑stabilized PVC cable conduit is essential to resist cracking and embrittlement from sunlight exposure, something standard plumbing PVC cannot offer. For more on material differences, see The PVC Pipe Institute.

Eliminate Interference

PVC is nonconductive, providing inherent electrical insulation that helps reduce incidental interference in mixed systems with sensitive electronics. Remember: nonmetallic conduit cannot serve as an equipment grounding path; always include a dedicated equipment grounding conductor in PVC raceways as required by code.

Keep Wiring Organized

Conduit keeps branch circuits and feeders neatly routed with accessible junctions and labeled transitions, improving serviceability and compliance with fill limits. Organized routing also supports consistent device termination practices throughout your project. For more safety tips and consumer guidance, visit the Electrical Safety Foundation International.

Source - eFIXX

What Is The Difference Between A PVC Pipe And Conduit?

Pressure Capacity

Plumbing PVC is pressure-rated for water systems, while electrical PVC conduit is designed solely to protect wiring and is not pressure-rated. Using the wrong product risks failure and code violations.

Colour and Identification

Plumbing PVC is typically white and marked for pressure and plumbing standards. Electrical PVC conduit is usually grey or black, with clear trade size and application markings such as “Sunlight Resistant.” These distinctions help ensure correct use and smooth inspections.

Wall Thickness and Flexibility

Plumbing PVC has thicker walls for pressure integrity, making it stiffer. Electrical conduit balances protection with flexibility, easing installation, especially in retrofit or tight-space scenarios. Fewer fittings mean faster, cleaner installs.

UV Degradation

UV‑stabilized PVC cable conduit is essential for outdoor runs, as it resists sunlight-related cracking and embrittlement. Plumbing PVC lacks this rating and is unsuitable for exterior electrical work.

Connections and Placement

Electrical conduit uses fittings, couplings, and belled ends rated for installs, with support intervals governed by code (see “NEC PVC conduit support spacing” below). Plumbing PVC employs couplers and solvent cements for pressurized systems; never mix components across categories.

Source- Ledes Group

What Are Plastic Conduit Fittings, And How Do They Work?

Conduit Bodies

Conduit bodies provide access for pulling, splicing, and directional changes while preserving bend radius. They come in various sizes and configurations (LB, LL, LR) and should be installed where access is needed for maintenance or future pulls.

Conduit Clips

Clips and clamps prevent sagging and maintain alignment. For compliance, follow NEC PVC conduit support spacing guidelines: secure conduit within 3 feet of terminations and at defined intervals along the run. Manufacturer datasheets often echo these requirements.

Conduit Couplings

Couplings join cut sections and transitions, with belled ends reducing the number of separate couplers needed. Always use listed, material-compatible couplings to maintain raceway integrity and marking continuity.

Finding The Best Conduit Fittings

Select listed fittings matched to conduit size and environment (indoor, damp, wet, corrosive, direct sunlight). Look for markings like “Sunlight Resistant,” “Limited Smoke,” or environment-specific notes. For specification support, consult NFPA 70 (NEC) and manufacturer catalogs.

Unicrimp’s range of conduit clips includes white cable clips designed for 22-26mm round fixtures. Made from high-grade polyethylene, these clips offer excellent flexibility in low-temperature environments, ensuring your wiring remains secure and organized. Properly installed conduit clips prevent damage to your wiring by keeping cables neatly in place, reducing the risk of wear and tear over time.

How Do You Run Cables And Wiring In Conduits?

The String Method

For short, straight runs, push a rod with a string attached, then use the string to pull conductors through. Protect insulation with compatible pulling grips and lubrication as recommended by the cable manufacturer.

A Conduit Piston

Conduit pistons (mice) use vacuum or air to shuttle a line through bends, then pull a rope for the conductors. This method is effective for complex but relatively short runs with multiple bends.

The Fish Tape Method

Fish tape is versatile for various lengths and geometries. Attach conductors with staggered heads and tape down sharp strand ends to protect the nylon jacket on modern building wire. For temperature swings on long outdoor runs, add expansion fittings and set supports to avoid buckling.

What Type Of Wiring Is Run Through Cable Conduits?

THWN Wires

THWN (Thermoplastic Heat and Water-resistant Nylon-coated) wire features thermoplastic insulation suitable for wet locations, with a nylon outer jacket for abrasion resistance. Many modern building wires are dual-rated THHN/THWN-2, expanding their suitability across dry and damp environments.

THHN Wires

THHN (Thermoplastic High Heat-resistant Nylon-coated) is a common 600V building wire, rated 90°C dry and often dual-listed for damp/wet use. Its nylon jacket reduces pull friction and improves durability, making it a practical choice for THHN vs THWN wire in conduit comparisons. Always verify ratings and environment requirements before installation.

Grounding Considerations

Rigid PVC is nonconductive and does not serve as an equipment grounding path. Always include a dedicated equipment grounding conductor in the conduit when required by code.

Additional Tips for Choosing and Installing Plastic Cable Conduits

- Assess Your Needs: Map cable count, insulation types, and environment (sunlight, moisture, chemicals), then select conduit marked and listed for those conditions. For safety planning, see HSE guidance on UK electrical standards.

- Quality Matters: Use listed, properly marked conduit and fittings; confirm “Sunlight Resistant” for exterior runs.

- Plan Your Layout: Minimize bends, respect bend radii, and position pull points per cable length and friction limits.

- Follow Standards: Align with NFPA 70 (NEC) for PVC, including NEC PVC conduit support spacing and expansion fittings for temperature-driven movement.

- Use Proper Tools: Select fish tape, appropriate pulling heads, and compatible lubricants to protect nylon jackets and maintain conductor integrity.

- Seek Professional Help: For complex or hazardous locations, consult a licensed electrician and reference current codes and manufacturer guidelines

.

Source -Electrical Code Coach

Why Choose Meteor Electrical for Your Plastic Cable Conduits?

Meteor Electrical offers a comprehensive range of plastic conduit fittings and accessories, including flexible, rigid, and specialty options, all designed for clean, compliant, and reliable installations. Our emphasis on UV stability, clear markings, and accessory compatibility means you get solutions tailored to real-world environments and code requirements.

- Extensive Selection: Flexible and rigid conduits for every application, with matching bodies, couplings, and clips.

- Quality Assurance: Products sourced for durability, UV resistance, and compliance with leading standards.

- Expert Support: Guidance aligned with NFPA 70 (NEC) principles for planning, spacing, and environment matching.

- Value and Convenience: Fast online ordering, competitive pricing, and reliable customer service.

Conclusion

Selecting the right plastic cable conduit is essential for safe, efficient, and code-compliant electrical work. For PVC electrical conduit for outdoor use, specify UV‑stabilized PVC cable conduit with appropriate fittings and adherence to NEC PVC conduit support spacing. Use THHN or THWN wire as needed, and always include a dedicated equipment grounding conductor in PVC raceways.

With Meteor Electrical, you get access to a curated selection of plastic conduit fittings and accessories designed for durability, flexibility, and ease of installation, helping you achieve professional results on every project. Whether you’re tackling a DIY upgrade or managing a large-scale installation, Meteor Electrical has the solutions and support you need.

Ready to get started? Explore our full range of PVC conduit and fittings, and shop with confidence at Meteor Electrical.

Visit Meteor Electrical today and take the next step toward safer, smarter electrical installations.

Frequently Asked Questions (FAQs)

1. What are the main advantages of using plastic cable conduits over metal conduits?

Lightweight, corrosion-resistant, flexible, and cost-effective. Non-conductive to reduce interference and simplify grounding, making installs faster and safer.

2. How do I determine the right size of PVC conduit for my electrical project?

Use NEC conduit fill tables to match conduit diameter to cable count and type. When unsure, consult a licensed electrician for code-compliant sizing.

3. Are plastic cable conduits suitable for outdoor installations?

Yes, choose PVC electrical conduit for outdoor use that’s clearly labeled “Sunlight Resistant” or UV‑stabilized PVC cable conduit and benefits from moisture resistance.

4. Can PVC conduits be used for plumbing purposes instead of electrical applications?

No. Electrical PVC lacks pressure ratings; plumbing PVC isn’t designed for wiring. Mixing them causes leaks, hazards, and code violations.

5. What are the best practices for installing conduit fittings to ensure a safe and efficient electrical system?

Align and secure runs, follow NEC PVC conduit support spacing, weather-seal outdoor connections, and use listed plastic conduit fittings and accessories matched to the environment.