What Size Of Gland Fits Your SWA Cable?

What Size Of Gland Fits Your SWA Cable?

Meteor Electrical's guide to finding out which size of gland best fits your SWA Cable

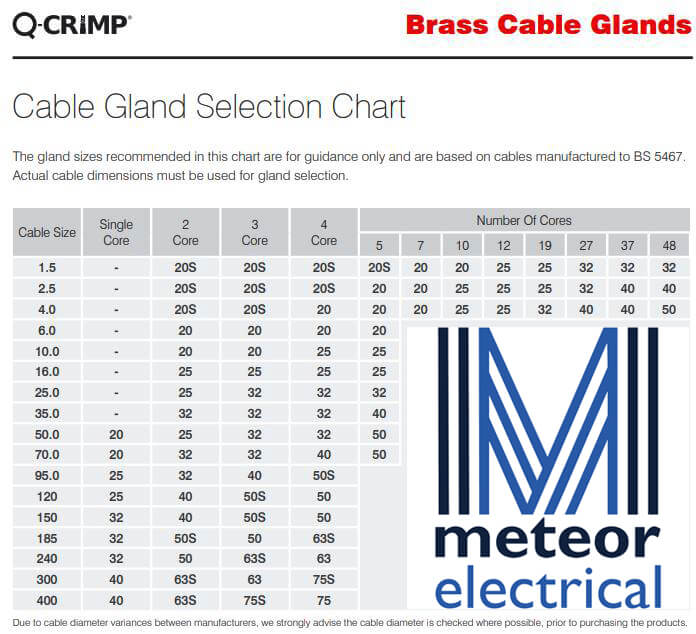

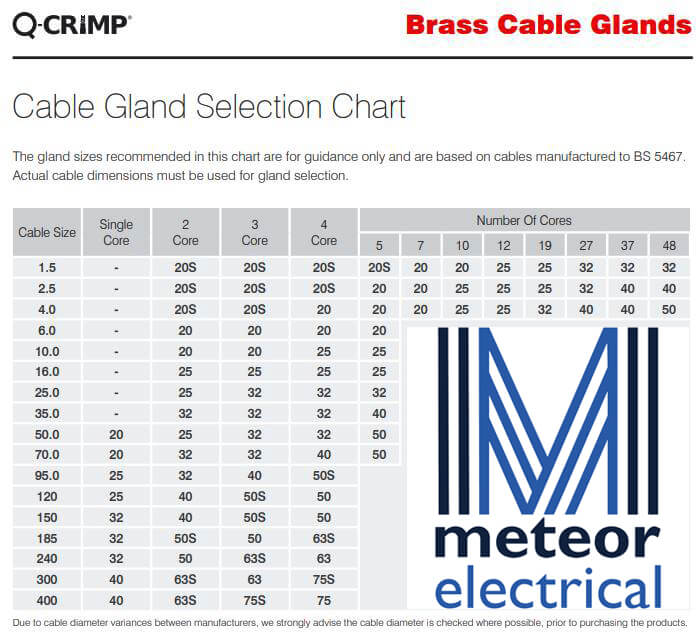

Steel Wire Armoured wire cable with varying diameters and core sizes will require different SWA gland sizes. Our handy SWA Cable Glands Size Chart can point you in the correct direction. In addition, if you visit our SWA cable gland page, you will notice that we have added different filter options to assist you in rapidly finding the suitable cable gland for your SWA cable.

SWA Glands Size Chart

This helpful chart offers you an instant reference point to help you make the right choice when buying Steel Wire Armoured Cable Glands for SWA electrical cables. If you require further assistance, contact our sales team. Or use this direct link to shop our range of SWA Glands

(Image of Meteor Electrical's SWA Gland Size Chart.)

This is from our selection of Q-crimp cable glands range. We sell these in varying swa gland packs, ready for next-day delivery.

What are SWA glands for?

SWA glands have an essential role when it comes to cable management. They are designed to attach and secure the end of an electrical cable and the device it is connected to. Cable glands provide earthing, grounding, insulation, bonding, and strain relief.

They can also be used to seal cables which pass through bulkheads or gland plates. Once you are able to select the right SWA gland size, you will be able to have adequate cable management set for areas with harsh or hazardous environments.

If the SWA cable gland is being used in unstable atmospheres, it is important for them to be approved for the selected type of cable to maintain the required level of protection.

Cable glands are typically made from metallic or non-metallic materials (or a combination of both), which makes them resistant to corrosion. This can be determined by selection to a standard or through corrosion resistance tests.

Now, you might be thinking what size SWA gland do I need? and how can you be sure the SWA gland size you choose is up to your application? Before getting into that, you will have to consider a various range of environmental and application factors.

Environment

SWA gland sizes aren’t the only things you need to worry about – you have to identify the core application environment of the cable gland you will be using regardless of the industry you’re in.

Some questions to consider include whether you are using the SWA gland indoors or outdoors, will it be situated in a safe or hazardous zone, what the temperature will be like and if it is constant. Other factors to consider are if the surrounding area is damp or dusty, and if there are any gases or corrosive materials around. Answering these questions will help you understand whether you need a special protective plating or coating for the swa cable gland size you choose.

Many cable glands come with additional environmental protection with how their out cable sheath is sealing, which helps it avoid dust and moisture from the electrical or instrument enclosure.

Difference between unarmoured and armoured cables

Depending on the type of cable it is, a different type of cable gland will be required. The requirements for an SWA cable, also known as an armoured cable, will not be the same as an unarmoured cable.

Armoured cables provide an extra layer of protection to prevent damage since they are often used on exterior walls or in places underground. This can be a single wire armour, braided armour, pliable wire armour, or double steel tape armour.

An unarmoured cable on the other hand is much more basic, and may have no seal or can have a single outer seal, or a double outer seal. It is usually used in fixed installations where it is not exposed to the risk of mechanical damage. While armoured cables do not need conduit because they are already armoured for protection, unarmoured cables will need it.

SWA Cable Gland Types

Metal SWA Cable Glands

Metal armoured cable glands are used in applications such as the chemical industry, technology, and generally in areas where there is a high demand for mechanical and chemical stability. They provide durability over time against different environmental conditions and have rigid stability.

Plastic SWA Cable Glands

Plastic SWA cable gland types are versatile due to their claw and seal design, which makes them durable and applicable in a range of applications. They are resistant to saltwater, grease and weak acids, etc.

How do SWA cable glands work?

Armoured cable glands are made by combining a central enclosure or body through which cabling can pass with several attachments. These are usually a lock nut, washers, seal, attachment claw or close, and a compression nut. Some SWA cable models also feature two-part enclosures, electrical earthing, PVC insulation, or rubber sealing.

The SWA gland size, arrangement, and design differ according to the type of cable gland. They are made out of a range of materials including PVC, PTFE, nylon, steel, aluminium, brass, and synthetic rubbers.

How to choose the right SWA gland size

Before you look at an armoured cable gland size chart, you have to consider some factors to determine the right SWA cable gland size. This will be the cable diameter, construction size, and cable material.

For armoured cables, consider:

- Diameter of inner bedding

- Diameter of lead covering

- Short circuit fault rating of the SWA cable armour

- Type and size of the armour braid

To make sure that you have picked out the right SWA cable gland size from the SWA gland size chart, ask yourself these questions:

- Is the SWA gland size wire hole diameter large enough to accommodate all the cables in the specific system?

- Is the SWA gland size cable diameter sufficient?

- Is the pressure rating of the SWA gland size you’ve picked high enough for your application needs?

- Is the SWA gland size mounting hold diameter large enough for your cable gland?

- Is the SWA gland size and depth thread metric or PG?

- Are there any specific requirements for stopper plugs to close off any unused SWA cable entries or not?

Meteor’s SWA gland size chart showcases the various cable sizes and the different cores available. They go from single to 48 core cables. The swa cable gland sizes are equal to the size of the cable bundle diameter. For example, if your SWA cable size in diameter is 50mm, then you should select the 50MM SWA cable gland only.

Meteor Electrical’s SWA gland size chart provides an instant reference point that will help you make the correct choice when buying an armoured cable gland. The size chart may not be enough, and if that’s the case then for further assistance, you can contact Meteor’s customer services.

What is a 20S SWA cable gland?

A 20S SWA cable gland is suitable for use with all types of armoured cables and provides an environmental seal on the outer sheath of the cable. It also brings the advantage of mechanical retention and electrical continuity via armour wire termination.

What is the difference between a M20 gland & a M20s gland?

The primary distinction between M20 and M20s is that M20s uses silica gel as the inner part material, changing the inner shape and enabling the usage of this material in new energy systems where it can withstand high temperatures for extended periods of time.